Digital Process Planning Software operates on PCs and tablets.

Press Release Summary:

To optimize shop productivity, NOVO™ v1.6 provides cloud-enabled digital tooling data and intelligence that seamlessly interfaces with production, inventory, and e-commerce. My Machines button, using basic information entered for shop’s machine tools, takes NOVO tooling recommendations and optimizes them for specific machine conditions. When Tool Advisor searches for cut-off applications, NOVO’s rules-based engine will return and rank most appropriate cut-off tool based on job conditions.

Original Press Release:

NOVO(TM) Extends Reach With New Version 1.6 for Tablets and PCs

Powerful cloud-enabled digital tooling data and intelligence seamlessly interfaces with production, inventory, e-commerce, and more to optimize shop productivity.

A better operation starts with better tools. Since its groundbreaking launch in 2013, Kennametal’s NOVO™ digital process planning application has continued growing by supplying complete tool data and process knowledge electronically, saving process planners, cost estimators, and manufacturing engineers countless hours of catalog lookups and process guesswork. That same intelligence for driving new efficiencies is now available on PC and tablet devices in the new Version 1.6.

“NOVO™ is an amazing vision of how far things can go to deliver powerful improved productivity to our customers,” says Katie Richardson, Kennametal’s director of program management for NOVO. Version 1.6 for PCs and tablets goes further with new features not available in previous versions.

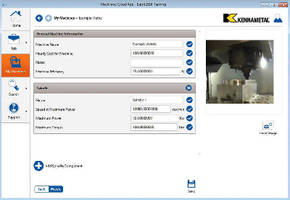

My Machines

By entering basic information for your shop’s machine tools, such as hourly cost, maximum spindle speed, and maximum torque, for example, a new “My Machines” button will take NOVO tooling recommendations and optimize them for your specific machine conditions. Such virtual machine libraries can also be shared across multiple users.

Also new to V1.6 is a turning cut-off advisor. Now when the Tool Advisor searches for cut-off applications, NOVO’s powerful rules-based engine will return and rank the most appropriate cut-off tool based on your job conditions.

For an extra level of efficiency, NOVO V1.6 for PCs and tablets now has a customer part-number capability. Many customers use their own nomenclature, and once this cross-reference is entered and populated for the first time, it will be stored and visible whenever NOVO is used. This makes it easy to connect tool selection to a customer’s internal systems.

Access to better data more quickly is key to productivity. With its open architecture, NOVO™ possibilities are limitless. NOVO is further evidence that “Different Thinking is Better Thinking.”

Download the app and signup for NOVO updates. Visit our YouTube channel to watch the exciting NOVO video: www.youtube.com/kennametalsolutions. For the latest news and updates, visit the NOVO website: http://www.kennametal.com/novo/?cid=a-14-03595_mb_novo

NOVO™ from Kennametal: a fundamental change in improving how work gets done.

Celebrating more than 75 years as an industrial technology leader, Kennametal Inc. delivers productivity to customers seeking peak performance in demanding environments. The company provides innovative wear-resistant products, application engineering and services backed by advanced material science, serving customers in 60 countries across diverse sectors of aerospace, earthworks, energy, industrial production, transportation and infrastructure. With approximately 14,000 employees and nearly $3 billion in sales, the company realizes half of its revenue from outside North America, and 40% globally from innovations introduced in the past five years. Recognized among the "World's Most Ethical Companies" (Ethisphere); "Outstanding Corporate Innovator" (Product Development Management Association); and "America's Safest Companies" (EHS Today) with a focus on 100% safety, Kennametal and its foundation invest in technical education, industrial technologies and material science to deliver the promise of progress and economic prosperity to people everywhere. For more information, visit the company's website at www.kennametal.com.

Kennametal Inc.

1600 Technology Way

PO Box 231

Latrobe, PA 15650-0231

USA

Kathy Linden

Phone : 724 539 5698

Fax : 724 539 6766

kathy.linden@kennametal.com

Kennametal Inc.

1600 Technology Way

PO Box 231

Latrobe, PA 15650-0231

USA

Carsten Gromoll

Phone : +1 724 539 8033

carsten.gromoll@kennametal.com