Diagnostic System monitors machine operating parameters.

Share:

Press Release Summary:

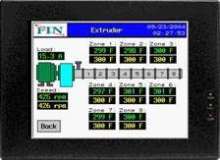

FIN EX(TM) system enables collection of information from legacy and base-line machinery that lacks built-in data gathering capabilities. It pinpoints and records operating data including temperature, speed, pressure, and other process variables. System includes 24 x 24 in. control panel, 10 x 10 in. color touch screen, and small PLCs that replace legacy temperature controllers. PC-based software collects, trends, and stores vital data.

Original Press Release:

New FIN(TM) System Monitors Critical Operating Parameters on Legacy Lines

WEST BERLIN, N.J., October 15, 2004 - Whether working with baseline or legacy machines, plant and maintenance managers share a common concern: How to effectively monitor critical production parameters. When seemingly simple actions, such as an operator changing the temperature settings, can overheat or burn a product, lead to defective parts, and necessitate expensive reruns, there is a clear need to effectively scrutinize machine parameters in a timely fashion. Managers need a simple to use, affordable, easy to install system that provides specific diagnostic capabilities for legacy production equipment.

Factory Intelligence Network (FIN), LLC has responded to this need with its recently released FIN EX(tm) system. FIN developed the system specifically to enable the collection of valuable information from legacy and base-line machinery that lacks built-in data gathering capabilities. FIN EX is a powerful tool to help managers diagnose operator and line issues, run their lines more efficiently, and improve product quality.

The FIN EX system pinpoints and records operating data including temperature, speed, pressure and other process variables.

"Until now there s been no affordable way to get critical production data from legacy equipment," said Ron Iannacone, president of FIN. "Plant managers had to fly blind, with no data on which to base decisions and improve line productivity. The FIN EX system gives them access to this information with just a few key strokes."

Prior to the launch of FIN EX at the Plastics U.S.A. Show in Chicago, Ill., Sept. 2004, even small changes in the production metrics of legacy and baseline processes and machines often resulted in defects that went unnoticed until it was too late to correct the problem. The FIN EX system, with its 24 x 24" control panel, 10x10" color touch screen, and small Programmable Logic Controllers (PLC) to replace legacy temperature controllers, records speed, pressure and other parameters. These PLCs are monitored by FIN EX s PC-based software that collects, trends and stores vital data. Operators use the touch screen to set and view temperatures, and other processes, while plant and maintenance managers can use the software to run trends and reports from their office PC.

About Factory Intelligence Network, LLC

Headquartered in West Berlin, N.J., Factory Intelligence Network (FIN) LLC was formed in 2003 by Automation & Control, Inc. (ACI), an industrial automation systems integrator and a master electrical contractor. ACI formed FIN to address the growing needs of manufacturers for an easy way to harness critical manufacturing data. FIN launched the first version of its Factory Intelligence system in 2001.