Delrin® Acetal Material comes in sheets and coils.

Press Release Summary:

Delrin® Forming Solutions offers high strength to weight ratio, high dimensional stability, scratch and wear resistance, low moisture vapor transmission rate, and chemical and solvent resistance. Surface readily accepts paints and inks. Delrin® FS comes in coils from .007-.125 in. thick and up to 24 in. wide, and sheets up to .250 in. thick and up to 48 in. wide. Metric sizes, up to 1250 mm wide, are available for international markets.

Original Press Release:

Penn Fiber Plastics Announces Availability of Dupont(TM) Delrin® Forming Solutions Thermoformable Acetal

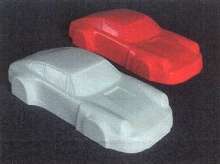

BENSALEM, PA. - Penn Fibre Plastics, Inc., an Ensinger Company. has announced immediate availability of a new thermoformable Delrin® acetal material in sheets and coils. The new material, designated Delrin® Forming Solutions (Delrin® FS), is the first acetal ever available in a thermoformable grade.

Delrin® FS opens the door for thermoformers to participate in the growing global markets for products made from acetal. Delrint FS delivers the same unique combinations of features as other Delrin® formulations do for injection molders and stock shape fabricators. These key features include a high strength to weight ration, high dimensional stability, superior scratch and wear resistance, a low moisture vapor transmission rate, and exceptional chemical and solvent resistance. As an added feature, this new Delrin® formulation has a surface that readily accepts paints and inks for decorating and printing applications.

Delrin® FS is available from Penn Fibre in coils from .007" to .125" thick and up to 24" wide. Sheets of Delrin® FS are available up to .250" thick and up to 48" wide. Metric sizes, up to 1250mm wide, are available for the international markets. Delrin® FS comes in natural (white) and a wide array of custom colors are available upon request. Glass filled and static dissipative grades are available on request.

Freetech Plastics Inc., of Fremont California, was the first thermoformer to sample the new material back in February of 2003. Freetech performed the first molding trials of Delrin® FS on a series of existing tools with excellent results. As a new materials development partner, Freetech provides guidance and technical support with all new materials developed for the thermoforming market by Penn Fibre.

Further validation of the forming abilities of Delrin® FS have been performed by Illig, GmbH, of Heilbronn, Germany. Illig sampled the material in various sizes and thicknesses and has produced a presentation containing processing parameters for the thermoforming industry. A copy of this presentation is available in PDF format by request.

The first formal introduction of the material took place at the DuPont(TM) Engineering Polymers booth at NPE last month. Encouraged visitors discussed applications for automotive, consumer electronics, medical devices and equipment, and industrial goods. Applications in thin gauge packaging markets are being developed at the time of this writing.

Delrin® FS is available directly through Penn Fibre in North America and through the global network of Ensinger companies in the international markets. For more information contact Penn Fibre Plastics at 800-662-7366, email to

penninfo@pennfibre.com, or visit our website at www.pennfibre.com.