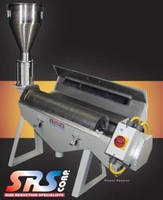

Dedusting/Fine Separation System uses rotating tumbling process.

Press Release Summary:

Capable of regrind throughput rates to 1,800 lb/hr with standard screen size of .125 in., SRS Deduster enhances molding procedures via removal of dust, powders, and fines from regrind or virgin material. System uses rotating tumbling process, sometimes with vacuum assist, and facilitates servicing/cleaning with full accessibility via tiltback cover. For operation, deduster requires 110 V single-phase or 230/460 3-phase electrical.

Original Press Release:

Size Reduction Specialists Announces Release of New Deduster

Enhance Molding Process by Removing Dust, Powders and Fines

EAST LANSING, MI, Size Reduction Specialists, known for the Bi-Cutter screenless granulator, today announces the release of the SRS Deduster. The SRS Deduster is a new, innovative, compact dedusting/fine separation system developed to enhance molding procedures by the removal of dust, powders and fines from regrind or virgin material. It uses a patented, rotating tumbling process (sometimes with vacuum assist) to remove powder and fines from the regrind or virgin material.

"I saw a need for a small, economical product," says Don Maynard, CEO of Size Reduction Specialists. "The small, compact footprint allows this Deduster to be easily installed and used press-side and/or in a central grind area. Full accessibility with a tiltback cover allows this unit to be serviced and cleaned-out easily, making it user friendly and reducing down time."

Initial Deduster system throughput testing far exceeded expectations at up to 1800 pounds per hour of regrind with a standard screen size of 1/8th inch (.125-inch). The Deduster requires 110v single phase, or 230 or 460 three phase electrical.

Two models (DFS-1236 and DFS-0618) of the Deduster is now available to order. Both units are compact and small. The main difference is in product throughput with the DFS-1236 producing up to 1800 pounds per hour and the DFS-0618 producing up to 800 pounds per hour. Custom applications and sizing is available to meet the customer's needs.

Model DFS-0618 will be on demonstration during the NPE 2012 show at booth #4153.

A discounted introductory price will also be available at the show.

With over 50 years combined experience in press-side screenless granulation, Size Reduction Specialists is the specialist in screenless granulation. In 1988, president and CEO Don Maynard helped Nissui Kako introduce the Nissui S-Cutter press-side screenless granulator to the U.S market. Before that time, screenless granulation was an "unknown" in the U.S. Then in 1997, SRS changed the industry by introducing the two-stage, press-side Bi-Cutter screenless granulator and fine separation equipment.