Deburring Machine works electrolytically.

Share:

Press Release Summary:

ECD Electrolytic Deburring/Contouring machine generates shapes and intricate contouring. Workpiece receives positive charge from anode contacts mounted on upper moving part of fixture. Material is selectively removed from positively charged workpiece when electrolyte is flushed between it and negatively charged electrode. There is no direct contact between tool and workpiece, resulting in no parts wear, distortion, mechanical stress, or tool wear.

ECD Electrolytic Deburring/Contouring machine generates shapes and intricate contouring. Workpiece receives positive charge from anode contacts mounted on upper moving part of fixture. Material is selectively removed from positively charged workpiece when electrolyte is flushed between it and negatively charged electrode. There is no direct contact between tool and workpiece, resulting in no parts wear, distortion, mechanical stress, or tool wear.Original Press Release:

Unmatched Method

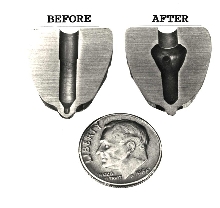

SurfTran Manufacturing Co., L.L.C. - Madison Heights, Michigan manufacturers of Electrolytic Deburring/Contouring machines provides a way to generate specific shapes where other methods fail. Shown is a cross-section of a small diesel engine injector component, which required controlled intricate contouring for improved flow characteristics. Several of these components are aligned in a fixture for producing accurate repeatable results for production.

ECD (Electrolytic Deburring/Contouring) works on virtually any metal or alloy, SurfTran has several types of electrolytes to match many of the metalworking industries applications.

How It Works-

Workpieces receive a positive charge from anode contacts mounted on the upper moving part of the fixture. Material is selectively removed from the positively charged workpiece when electrolyte is flushed between it and a negatively charged electrode.

There is no direct contact between the tool and workpiece, resulting in no parts wear, distortion, mechanical stress or tool wear.

SurfTran's Cationic systems range from standard single station machines to totally automatic transfer lines. SurfTran also builds Thermal Energy Method deburring/deflashing machines and Aqueous cleaning systems.

Please send inquiries directly to:

SurfTran Manufacturing Co., L.L.C.

30250 Stephenson Highway

Madison Heights, Michigan 48071

Attention: Eden Diver

(248) 547-3133

Fax (248) 547-0206