Mechanical Wire, Cable and Rope

Deburring Machine burns off burrs with high heat.

Share:

Press Release Summary:

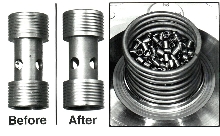

Thermal Energy Method system vaporizes burrs, flash, and contaminants on hundreds of small parts internally and externally with bursts of high heat. It can deburr cast iron, steel, stainless steel, aluminum and brass, and deflash zinc parts. It works by loading parts into deburring chamber, where mixture of gas and oxygen is introduced, completely enveloping the parts. Spark ignites mixture, creating intense burst of high heat which blasts burrs.

Thermal Energy Method system vaporizes burrs, flash, and contaminants on hundreds of small parts internally and externally with bursts of high heat. It can deburr cast iron, steel, stainless steel, aluminum and brass, and deflash zinc parts. It works by loading parts into deburring chamber, where mixture of gas and oxygen is introduced, completely enveloping the parts. Spark ignites mixture, creating intense burst of high heat which blasts burrs.Original Press Release:

Multiple Parts Thermally Deburred Inside & Out

SurfTran Manufacturing Co., L.L.C.- Madison Heights, Michigan builders of Thermal Energy Method (TEM) deburring and deflashing systems that efficiently and economically deburr cast iron, steel, stainless steel, aluminum, brass, and deflashes zinc parts.

Dozens to hundreds of small parts with burrs or flash and metal contaminants are bulk loaded into a parts holder, the TEM system then vaporizes the burrs, flash and contaminants internally and externally with a burst of high heat. The Thermal Energy Method removes them all, which conventional tumbling and brushing often cannot remove.

SurfTran builds a variety of TEM machines for deburring and deflashing small to large parts, these machines can be fully automated for high production requirements.

How does the Thermal Energy Method work? The parts are loaded into a parts holder, then indexed to under the deburring chamber, they are sealed inside the chamber, a mixture of gas and oxygen is introduced- completely enveloping the parts, a spark ignites the mixture creating an intense burst of high heat which vaporizes all burrs, flash and metallic contaminants internally and externally. Without parts wear, media and metallurgical change.