Deburring/Finishing Machine features spiral design.

Press Release Summary:

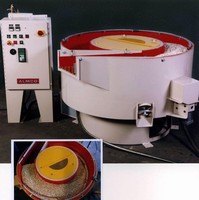

Model SBB-12 spiral bottom round bowl unit includes full-circle baffle that keeps parts constantly in media mass. Spiral design of up-hill tub bottom enables automatic separation of parts from abrasive media at pre-determined intervals, and allows different parts to move over separating dam to screening area without jamming or hitting. Device features 12 cu ft urethane-lined tub, 7.5 hp drive, 13 in. dia tub cross section, with 66 in. overall diameter and 44 in. height.

Original Press Release:

New Spiral-Bottom Round-Bowl Machine Introduced by Almco at IMTS Event

Unique Baffle Enhances Speed, Precision; Long Screen Allows Faster Parts/Media Separation

ALBERT LEA, Minnesota (September 11, 2006) - ALMCO, Inc., the world's largest manufacturer of automated metal parts deburring and finishing equipment, has expanded its line to include a spiral-bottom round-bowl unit with a unique full-circle baffle that keeps parts in the media mass constantly for faster, more precise processing.

The new Model SBB-12, introduced at the 2006 International Manufacturing Technology Show (IMTS) in Chicago, has a 12-cubic-foot, urethane-lined tub for parts protection. Other models initially available have tub capacities of 8 and 15 cubic feet; custom-designed models will offer capacities up to 100 cubic feet, the company notes.

ALMCO's new spiral design features automatic separation of parts from the abrasive media, at pre-determined intervals according to finishing requirements. Its separating screen surface is longer than other round-bowl designs, which permits faster separation of parts and machine unloading.

"Very importantly," says ALMCO's national sales manager, Larry Beavens, "our

customers can be certain of an exceptionally durable, long-lasting machine in this new design, just as they find in the other round-bowls and all other finishing equipment we produce. Not only do we have exceptional engineering skills in our company, our renowned manufacturing capabilities assure longevity and reliability backed by an unusual level of technical service."

The SBB-12 is designed, Beavens notes, to lift and move many different parts positively over the separating dam without jamming or hitting each other on the screen. The tub can also serve as a thru-feed or one-pass machine - adding to the SBB's versatility - when the dam is held in the up position.

Key benefit of the spiral design is its up-hill tub bottom that provides a larger rolling mass right to the screen area. This allows larger parts to be lifted up the dam and over the screening area. Larger parts can be processed in the tub because of greater clearance between the screen and tub bottom.

Specifications of the SBB-12 include a 7.5-hp drive, a 13-inch diameter tub cross section, an overall diameter of 66 inches, and a machine height of 44 inches. Separate from a free-standing control panel, floor space requirement is less than 6 feet square.

For further information, contact ALMCO, Inc., 507 West Front Street, Albert Lea, Minnesota 56007, phone 1-800-521-1740, or visit the company on the Internet at www.almcoinc.com. In addition to its metal finishing and deburring equipment, the 65-year-old manufacturer is a leading producer of parts cleaning and liquid filtration equipment and systems, all of which are sold through an international network of independent distributors, sales representatives and ALMCO region managers.