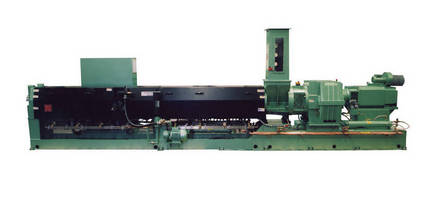

Davis-Standard Recycling Lines Deliver on Rates and Quality

(Pawcatuck, Conn.) - Innovative HDPE recycling combined with high performance Davis-Standard equipment has equated to substantial growth for Engineered Recycling Company (ERC) of Charlotte, North Carolina. Since installing a Davis-Standard Merritt Polycycle® line in 2007 and a second identical line in 2009, ERC has increased rates, throughputs and processing flexibility. The company is one of the largest producers of high molecular weight (HMW) pellets in North America, and recently expanded its fractional melt HDPE pellet capacity. To better support customers, ERC has increased its Charlotte facility to 170,000 square feet (15,793 square meters) and looks to add a second facility in the Midwest in the near future.

"We chose Davis-Standard based on quality and reputation. They specialize in extruders and that is evident. We had good discussions with their engineers regarding screw design, feed throat design and accessory equipment," said Peter Suttoni, president. "For example, we asked Davis-Standard to tie in screen changers that worked with our underwater pelletizing systems and they did. Everything has been well integrated and has performed as promised."

Davis-Standard designed ERC's Polycycle lines with 600 hp drives and specialized feed throats to handle various materials. These lines are designed to go from scrap to pellet, combining the steps for size reduction, storage, melting, devolitization, filtration and pelletization. ERC runs a high-volume operation by shredding, washing and pelletizing 600,000 pounds (272,160 kg) of reclaimed plastic per week. Bales of material are brought into the facility, size reduced, washed and dried, and then extruded into high molecular weight HDPE or fractional melt HDPE. The company also offers hybrid material blends, which combine HMW and fractional melt materials. ERC offers customers resins of such a high quality that they can be run at 100 percent rates or used as a drop-in substitute for virgin resins.

"Davis-Standard engineers understand how important good screw design is to product quality. Our parts and screws are interchangeable, enabling us to run our product on either line," explained Suttoni. "The screws also help eliminate melt fracture so that we are not degrading the polymer as we process it. We have set aggressive rates and goals for our operation. We would not be able to achieve these rates and this quality without Davis-Standard's equipment."

ERC was founded in 2000 and has built a solid reputation in recycling HDPE as well as plastics molding and premium recycled pellets. The company has an annual capacity to produce 50 million pounds (23 million kg) of pellets used in blow molding, injection molding, extrusion and thermoforming applications. ERC's customers are all U.S.-based, and make everything from plastic pipe, doubled walled cases and nursery containers to automotive products and plastic drums.

For more information about ERC, visit www.erecycling-usa.com. For more information about Davis-Standard's Merritt brand recycling equipment, contact Steve Kriger at skriger@davis-standard.com.

CONTACT

Luann Kupka

Marketing & Sales Administration Manager

Extrusion Systems

860-599-6262