Cutting Tool Inserts last 40% longer than before.

Press Release Summary:

CoroCut(R) parting and grooving tools provide good surface finish and have 20 to 40% longer tool life than previous tools. They withstand high axial cutting forces, maximize feed without vibration, and work on materials ranging from aluminum to hardened steels and heat resistant super alloys (HRSAs). Tools are available in Grade H10 carbide, in PVD-TiAIN coated carbide grades, and in four geometries. Variety of toolholders and bars are available.

CoroCut(R) parting and grooving tools provide good surface finish and have 20 to 40% longer tool life than previous tools. They withstand high axial cutting forces, maximize feed without vibration, and work on materials ranging from aluminum to hardened steels and heat resistant super alloys (HRSAs). Tools are available in Grade H10 carbide, in PVD-TiAIN coated carbide grades, and in four geometries. Variety of toolholders and bars are available.Original Press Release:

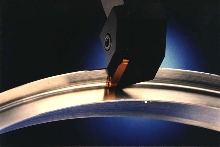

New Parting And Grooving Tools Improve Productivity, Last Up To 40% Longer

An extended line of parting and grooving tools is now available from Sandvik Coromant. The new CoroCut(R) family members improve chip control, lower inventory costs, and provide good surface finish and 20 to 40% longer tool life than comparable tools. In addition, they enhance productivity and eliminate machining hassles in materials ranging from aluminum to hardened steels and heat resistant super alloys (HRSAs).

Four new geometries, two new carbide grades, and a wider variety of toolholders and bars are now available.

CoroCut tools are designed to withstand high axial cutting forces and provide unmatched strength and stability to maximize feed without vibration. The new, full-radius, CoroCut 2-edge, AM geometry insert for aluminum profiling strengthens clamping support, and reduces vibration. It is available in Grade H10 carbide in .236 in. (6 mm) and .315 in. (8 mm) widths.

The new, precision-ground GF geometry insert holds tighter tolerances. The CoroCut 1-edge CR and Q-Cut 7P geometries offer improved chip control. The CR geometry insert features reinforced edges and is ideal for deep parting operations. The Q-Cut 7P geometry insert is best suited for first cuts and side turning.

New PVD-TiAIN coated carbide grades include the GC1005 and 4125 optimized for machining HRSAs and stainless steels at 20 to 25% higher cutting speeds than conventional grades. Ideal for gas turbine machining, both provide high wear resistance, good surface finish, and optimal chip formation.

Lower Inventory, Too

CoroCut and Q-Cut toolholders now come in 0 and 90-degree styles and Q-Cut bars in 0 degree versions for internal face grooving. The new holders can hold multiple seat sizes. The strong clamping system provides exceptional accessibility for shallow grooving. The CoroCut 1-2 edge system covers first-cut diameters from 1.339 in. (34 mm) and the Q-Cut system from 0.945 in. (24 mm). The cutters lower inventory costs since one holder accommodates both one and two-edge CoroCut inserts.

Sandvik is an international group of materials-technology companies with 34,000 employees in 130 countries and over $5 billion in annual sales. Operations worldwide comprise three separate business areas: Tooling, Specialty Steels, and Mining and Construction. The Sandvik US group represents all three business areas, exceeding $1 billion in annual sales.

Products include cemented carbide and high-speed steel tools for metalworking; machinery and equipment for mining and construction; and stainless steels, special alloys and heating materials. Each company in the Sandvik group prides itself on large investments in research and development, a strong commitment to superior customer service and the willingness and capability to lead the way in technology.

For more information contact Thomas Carlberg, Sandvik Coromant, 1702 Nevins Road, Fair Lawn, NJ 07410; email thomas.carlberg@sandvik.com; phone (201) 794-5000; fax (201) 794-5217, www.coromant.sandvik.com.