Custom Gripping Solutions for the Fastener Industry

Share:

Hardinge manufactures collets for all brands of machines and adapters used in the fastener industry. They engineer precision collets to grip blind bolt fasteners, solid and blind rivets, bolts, screws, nuts, inserts and studs. A majority of these fasteners are used in the global aerospace market. "We have many proven collet solutions used in the aerospace fastener industry, states Tom Mitchell, general manager at Hardinge Workholding. We have provided over-the-shoulder gripping, solutions for non-marking and can incorporate features such as coolant flushing into the collet design. We will provide micro surface finishes and critical radii with any additional inspections that may be required for the application." Hardinge workholding design and applications engineers will also work with other machine tool builders for complete turnkey packages. Along with aerospace Hardinge supports the automotive, commercial transportation, defense and industrial markets with these products.

Gripping Rivets

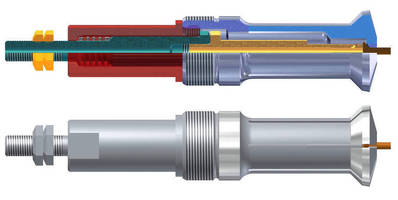

The over-the-shoulder pickoff collet assembly shown is designed for the manufacture of rivets and is based on a modified 5C collet and ejector stop. This combination enables the customer to take advantage of automation including robot loading. A flat face and a short bearing allow essential robot gripping access. The rivets are automatically spring-ejected into a parts bin when the collet opens. This design features thru-coolant capability.

The collet shown on the left features three internal tapered cavities to support thru-spindle coolant flushing for boring, drilling or tapping. The gripping surface (order hole) and the locating chamfer at the opening are hard turned to a specified micro finish. The collet on the right is a 5W over-the-shoulder (over-grip) collet. This design incorporates six slots with an oval relief in each slot. The double-angle taper and short bearing surface allow and overgrip to swallow the rivet head in the back drill area inside the collet in order to grip the shaft byond.

Gripping Blind Fasteners

Over-the-shoulder collets similar to the 5W are used for blind fasteners when required to clear a head and grip on a smaller diameter beyond. Extra spread is required to open the collet wide enough to go over the larger diameter. Hardinge incorporates multiple slots with an oval or teardrop relief at the end of the slots and reduced wall thickness for maximum flexibility to open and close the collet accurately and repeatedly. The relief takes the stress of the wide spread and helps to maintain roundness at the back bearing of the collet. A double-angle taper reduces the contact surface, and allows maximum spread for quick opening of the collet. A back drill area behind the gripping surface (order hole) will accommodate the head of the fastener or screw.

Monogram Aerospace Fasteners, a blind bolt manufacturer located in California turned to Hardinge for a collet that would control part quality and concentricity, at a cost advantage, according to Monogram's VP of manufacturing. One particular job at Monogram involved hard material, cutting off to length, nosing the taper angle and tapping the fastener body.

Hardinge is the world's largest manufacturer of collets, feed fingers and pads. They have been manufacturing collets since the concept of the 5C collet in the 1890's. A significant portion of their workholding business is custom manufacturing. At Hardinge the custom manufacturing is separated from the standard products in order to better serve the customer. Hardinge employs a full staff of manufacturing, design and application engineers and experienced phone correspondents to handle the custom product requests exclusively. They walk and talk "modified and non-typical gripping solutions" all day long. Hardinge manufactures to rigid specifications including material, heat treatment and accuracy and is pre-approved as a government vendor.

Hardinge is continuously improving their facility with machinery and software upgrades and lean-manufacturing processes including current workflow reorganization within the facility. Drawings and sample parts can be sent to Hardinge Inc., One Hardinge Drive, Elmira, New York 14902; email to info@hardinge.com; fax 607-737-0090; or phone 800-843-8801.

Linda Folkers

Advertising Manager, Workholding

607-378-4328

linda.folkers@hardinge.com