Coordinate Measuring Machine allows direct computer control.

Share:

Press Release Summary:

DCC GAGE(TM) Measurement Station can be used as stand-alone, walk-up station for first piece inspection, layout inspection and tool setup, or as flexible gage. It handles workpieces up to 18 x 20 x 16 in. and offers speed of 305 mm/sec. PC-DMIS PRO(TM) software provides shop-floor graphics interface that guides operators through part programming, setup, and execution of inspection routine. DCC GAGE includes TP-ES probe, computer system, and 15 in. monitor.

DCC GAGE(TM) Measurement Station can be used as stand-alone, walk-up station for first piece inspection, layout inspection and tool setup, or as flexible gage. It handles workpieces up to 18 x 20 x 16 in. and offers speed of 305 mm/sec. PC-DMIS PRO(TM) software provides shop-floor graphics interface that guides operators through part programming, setup, and execution of inspection routine. DCC GAGE includes TP-ES probe, computer system, and 15 in. monitor.Original Press Release:

DCC Gage Offers Cost Effective Automated Measurement

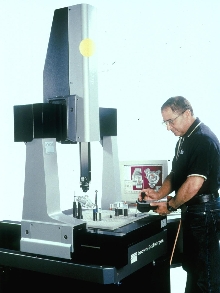

NORTH KINGSTOWN, RI--The new DCC GAGE(TM) Measurement Station from Brown & Sharpe is an entry level, high performance direct computer control coordinate measuring machine designed to improve throughput and accuracy in a variety of measurement and inspection operations.

The DCC GAGE can be used as a stand-alone, walk-up station for first piece inspection, layout inspection and tool set up, or as a flexible gage. Its large measurement envelope can handle workpiece sizes up to 18" X 20" X 16" (457 mm X 508 mm X 406 mm). With a speed of 305 mm/second and acceleration of 290

mm/second2, the DCC GAGE easily keeps pace with machine tools. In many applications, DCC GAGE can improve inspection efficiency up to 45 percent, significantly reducing machine tool idle time.

The DCC GAGE comes equipped with PC-DMIS PRO(TM) software. This

powerful new software features an easy-to-use, shop-floor graphics interface that guides operators through part programming, setup and execution of the inspection routine.

Advanced graphics reporting functions assist users in configuring inspection results to meet specific data analysis needs. The DCC GAGE is also equipped with a TP-ES probe, a computer system and a 15" monitor. The purchase price includes

installation, training and a one-year warranty on parts and service.

For additional functionality and flexibility, users can upgrade the DCC GAGE with the addition of PC-DMIS CAD(TM) or PC-DMIS CAD++(TM) software. PC-DMIS CAD uses 3D CAD data to create part programs, both on and off-line, complete with graphical part models and probe path simulations. PC-DMIS CAD++ software

incorporates a scanning function for the accurate measurement of complex shapes such as turbine blades, dies, models, sheet metal components and other curved shapes quickly and efficiently.

Part programs can be created directly from CAD models using native CAD system algorithms and tools with either the DIRECT CAD TRANSLATOR(TM) (DCT) or the DIRECT CAD INTERFACE(TM) (DCI) options to both PC-DMIS CAD and PC-DMIS CAD++. DCT serves as a translator while DCI eliminates the need for any translator by using the original CAD model, assuring no accuracy is lost when design data is used for part programming. The result is reduced programming time, greater measuring accuracy and improved inspection throughput and efficiency.

Brown & Sharpe, 200 Frenchtown Road, North Kingstown, RI

02852-1700, 1-800-766-4673, FAX (401) 886-2727, www.brownandsharpe.com.