Conveyor Engineering & Manufacturing Develops the Dura-Link(TM) Screw Conveyor Coupling

Conveyor Engineering & Manufacturing has recently developed the Dura-Link™ screw conveyor coupling to reduce costly screw conveyor downtime by making shaft removal quicker and easier during repairs.

Cedar Rapids, IA -- Conveyor Engineering & Manufacturing has recently developed the Dura-Link™ coupling to reduce costly screw conveyor downtime.

Replacing a screw conveyor component (drive shaft, screw, coupling shaft) typically requires the time consuming process of moving adjoining components. Dura-Link™ couplings allow for direct replacement without this costly step.

Light duty, removable key couplings have been available in the past but they have always sacrificed strength and durability. Dura-Link™ couplings finally make this option available in a much more durable design that is necessary for critical conveyors.

According to CEMA (Conveyor Equipment Manufacturers Association), the necessary screw modifications for standard quick links or quick keys reduce pipe strength by approximately 45%. Conveyor Engineering & Manufacturing’s “Snug Wrap™” design gives you couplings that don’t require that compromise.

You can now have the best of both worlds; quick and easy component replacement in a strong, durable design.

Conveyor Engineering & Manufacturing is a full service supplier of screw conveyor equipment and general fabrication specialization in stainless steel. The company was established in a small shop outside Shueyville, Iowa in 1977 and now resides in a new 116,000 square foot location in Cedar Rapids, Iowa.

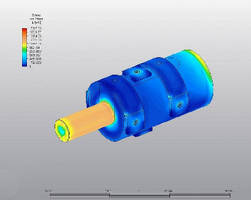

Conveyor Engineering & Manufacturing offers full service engineering capabilities ranging from FEA Analysis to System 3-D Modeling. Manufacturing capabilities are enhanced by the latest in equipment operated by well trained and experienced operators.