Conformal Coating Inspection System exposes potential defects.

Press Release Summary:

Featuring 8M camera technology with 4 orthogonal cameras and UV LEDs, S3088 Conformal Coating Inspection (CCI) system inspects transparent protective coatings with UV fluorescent indicators on electronics assemblies for such defects as cracks, bad spots, thin/thick layers, smearing, impurities, or splashes. Along with 11.7 or 23.5 µm/pixel resolution, features include flexible algorithms for adaptation to different conformal coating methods. Inspection programs can be created within minutes.

Original Press Release:

Viscom S3088 CCI Inspects Conformal Coatings of Electronic Assemblies

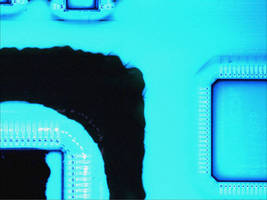

Hanover – Transparent protective conformal coating protects electronics assemblies against damage from moisture and wetness. The new Viscom S3088 Conformal Coating Inspection (CCI) system inspects coatings quickly and reliably for typical defects such as cracks, bad spots, layers that are too thin or too thick, smearing, impurities, or splashes. Transparent protective coatings contain UV fluorescent indicators that emit visible light, allowing automatic optical inspection. The Viscom S3088 CCI system features an 8M camera technology with four orthogonal cameras and also is equipped with UV LEDs. The S3088 CCI system is immediately available worldwide.

Electronics manufacturers use the Viscom S3088 CCI at the end of the process chain after lacquering and drying. “The new inspection system that inspects the conformal coating is an integral part of the Viscom product family. The S3088 CCI works with the Viscom SI inspection software, thus offering the same user interface and programming strategy,” said Detlef Beer, responsible for product development at Viscom. “This basis makes it possible to implement traceability concepts, special tests such as reading labels with a data matrix code (DMC) and other features. As a result, the system also can be integrated in production control systems, making it a Manufacturing Execution System (MES).”

Technologically, the S3088 CCI is based on the successful Viscom S3088 system. It works with UV LEDs, which contrasts the UV-reactive conformal coating with the background material, clearly detecting the contours of the lacquer. “With a resolution of 11.7 or 23.5 µm/pixel, even the smallest bad areas, contaminations or splashes are clearly visible. These then are classified either as defects or as providing valuable indicators to further optimize the coating process,” Beer continued. In this way, the Viscom S3088 CCI ensures that electronics manufacturers reliably comply with the IPC-CC-830 directive for the qualification and performance of electrical insulating compounds for printed circuit boards.

As a result of flexible algorithms, the system can be quickly adapted to different conformal coating methods. Simple inspection programs can be created in only a few minutes. Additionally, it features a good price/performance ratio: An S3088 CCI system is more economical than a classic AOI system. The inspection system is thus intended for electronics manufacturers who apply conformal coatings to large- and medium-sized quantities of electronics assemblies in fields such as automotive engineering, aerospace, industrial electronics and medical technology, among others.

Viscom AG

Viscom AG develops, manufactures and sells high-quality inspection systems. The portfolio encompasses the complete bandwidth of optical and X-ray inspections. In the area of assembly inspection for electronics manufacturing, the company is among the leading suppliers worldwide. Viscom systems can be configured specific to the customer and can be interlinked. The company headquarters and manufacturing location is in Hanover, Germany. With a wide network of branches, applications centers, service support points and representatives, Viscom is represented internationally. Founded in 1984, Viscom has been listed on the Frankfurt Stock Exchange (ISIN: DE0007846867) since 2006. For additional information, visit www.viscom.de.