Conductive Electrical Adhesive suits applications to 500°F.

Press Release Summary:

Offering alternative to silver-filled, electrically conductive epoxies, nickel-filled Duralco 122 cures at room temperature in 16-24 hr at 75°F or can be fast cured in 10 min at 200°F. Resistant to moisture, chemicals, and solvents, 2-part epoxy bonds well to glass, ceramics, plastics, dissimilar materials, and metals, including steel, stainless, aluminum, and lead. It is suited for flexible circuits, semiconductors, EMI shielding, thermistors, wire tacking, and heating elements.

Original Press Release:

Low Cost, Nickel Filled Conductive Electrical Adhesive up to 500ºF

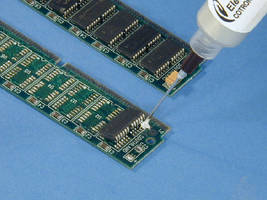

Duralco 122 nickel filled adhesive and casting epoxy is specially formulated to provide a low-cost, economical alternative to silver filled, electrically conductive epoxies. Duralco 122 is the perfect solution for electrical and industrial applications that require a low cost, electrically conductive adhesive.

Ideal for manufacturing and repairing of flexible circuits, solder replacement, bonding semi-conductors, EMI shielding, thermistors, wire tacking, heating elements, assembling, electronics, etc. This two-part epoxy is mixed by hand and flows better. The mixed epoxy cures at room temperature in 16-24 hours at 75ºF or can be fast cured in 10 minutes at 200ºF. For optimum conductivity, adhesion and strength, post cure at 250º for 2 hours.

The nickel based Duralco 122 conductive epoxy bonds exceptionally well to glass, ceramics, plastics, metals including steel, stainless, aluminum and lead as well as dissimilar materials. Epoxy is resistant to moisture, chemicals and solvents.

For more information write, call, fax or visit: www.cotronics.com