Coil Heater compensates for thermal expansion.

Press Release Summary:

Wedge locking, injection-nozzle heater, with clamping band, allows heating element to maintain full clamping force at elevated temperatures. Rectangular profile of heating element increases surface contact of heater and injection nozzle. Flexible element extensions terminate to Teflon(R) leadwires with moisture-resistant seals. Resistance tolerance is +/-2%. Standard sizes are 0.750 in. ID and 1.20 in. length.

Wedge locking, injection-nozzle heater, with clamping band, allows heating element to maintain full clamping force at elevated temperatures. Rectangular profile of heating element increases surface contact of heater and injection nozzle. Flexible element extensions terminate to Teflon(R) leadwires with moisture-resistant seals. Resistance tolerance is +/-2%. Standard sizes are 0.750 in. ID and 1.20 in. length.Original Press Release:

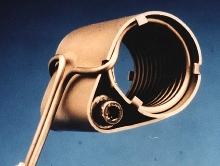

Wedge-Locking Coil Heater For Injection Nozzle

Durex Industries introduces a mini coil heater with a unique clamping band which allows the heating element to maintain full clamping force at elevated temperatures. Unlike conventional

cam-locking designs, this, wedge-locking mechanism compensates for thermal expansion.

The tubular heating element is constructed in a rectangular profile to significantly increase surface contact of the heater and injection nozzle, resulting in a more efficient heat transfer.

A standard Allen wrench tightens the wedge lock clamping mechanism to user requirements, another advantage over the cam-locking designs.

Flexible element extensions terminate to Teflon® leadwires with moisture-resistant seals. Each coil heater is manufactured by Durex with a resistance tolerance of ±2%. Standard sizes in

.750" I.D. and 1.20" length are in stock in various wattages and can be supplied with a Type J or K thermocouple.

For more information and literature, please contact: DUREX INDUSTRIES, 190 Detroit Street, Cary, IL 60013-2979. TOLL-FREE: 1-800-762-3468. Phone (847) 639-5600. Fax: 847-639-2199, Web: www.durexindustries.com Email: sales@durexindustries.com Atten: Randy Nelson