CNC Workholding Systems offer operational flexibility.

Press Release Summary:

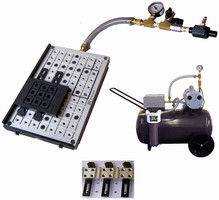

Pallet-Vise may be used as stand-alone solution for machining or in multiple-pallet configuration for larger parts or high-volume production. Alternatively, Vac-Vise may be used as vacuum chuck or pallet system simultaneously to hold various workpiece shapes and sizes. Both allow machining and marking of workpieces without custom fixtures and are designed to facilitate creation of repeatable procedures. Adjustable hex workstops and edge clamps are available to promote flexibility.

Original Press Release:

Innovative Design Improves CNC Workholding and Fixturing

Flexible Systems Offer Quick Part Prototyping And Effective High Production Machining

Source: 2L inc., Hudson, Massachusetts - 2L inc. announced today that it was ending its prototyping activity and offering its' new patent pending Vac-Vise and Pallet-Vise workholding and fixturing systems on a full commercial basis.

The Pallet-Vise Workholding System can be used as a stand-alone workholding solution for typical machining or used in a multiple pallet configuration for large parts or high volume production. The Vac-Vise Workholding System can be used as a Vacuum Chuck or Pallet System simultaneously to hold a wide variety of workpiece shapes and sizes.

Both the Vac-Vise and Pallet-Vise Systems allow the machining and marking of workpieces quickly without spending the time or money on custom fixtures. Both systems have been designed so machinists can create easy repeatable procedures. Locations are numbered and easily identified across multiple pallets allowing for fast and easy set up, and consistent positioning of your workpieces when used in high production machining.

2L's patent pending Adjustable Hex Workstops and Edge Clamps can be used with both the Vac-Vise and Pallet-Vise Workholding Systems to achieve maximum flexibility. Their unique design provides the ability to hold challenging workpiece sizes and shapes, including thin or small parts, corners, and odd shaped parts that are typically difficult to hold. Their low profile design allows for optimal tool clearance and protection. When used with the Adjustable Hex Workstop the Edge Clamps provide a clamping travel range of 1.25" to securely hold the workpiece.

When using the Vac-Vise Vacuum Chuck, the vacuum can be created by using the 2L Oilless Electric Portable Vacuum Pump System, or a 2L Venturi Vacuum and a standard shop air compressor.

A company spokesman said, "The combined use of the Vac-Vise Vacuum Chuck, Pallet-Vise and Adjustable Hex Workstops and Edge Clamps allows the typical machine shop maximum flexibility in getting their job done with little set up and expense." "Both the Vac-Vise Vacuum Chuck and Pallet-Vise System effectively hold difficult workpieces and support an easy repeatable set up." "Additionally, we use only heat treated steel for our Adjustable Edge Clamps to ensure long-term durability when machining." "We are especially pleased to be able to offer these products and use them in our own manufacturing processes."

Please refer all inquiries to the Marketing Department at:

2L inc., P.O. Box 105, Hudson, MA 01749, (978)567-8867, 2Linc.com

About 2L inc.

Since 1998, 2L inc. has been designing, developing, manufacturing, and distributing innovative tools and product solutions for the manufacturing, engraving, and industrial markets.