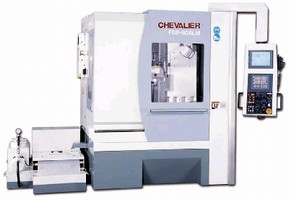

CNC Profile Grinder accelerates up to 2.5 G.

Press Release Summary:

Combining linear motor drive and 3-axis closed-loop electronic control, Model FPG-608LM delivers reciprocating rate of 720 times/min at 5/8 in. stroke and 328 fpm table speed. Machine offers 6 x 8 in. work area, 0.0001 in. X and 0.000040 in. YZ axis repeatabilities, and 2,000-10,000 rpm spindle speed. Adjustable grinding head swivels with ±5° range to meet various applications. Control options include FANUC 18iM with FANUC linear motors or Smart control using Siemens linear motors.

Original Press Release:

New Chevalier Grinder Accelerates Up to 2.5G

Chevalier's new FGP-608LM combines linear motor drive, 3 axis closed loop electronic control and structural stability to deliver up to 2.5G accel/decel speed, 720 times per minute reciprocating rate at 5/8" stroke and 328fpm table speed. Heavily ribbed solid Meehanite cast iron castings with hardened and ground linear ways on XYZ coupled with the company's heavy duty spindle enable the machine to operate without vibration during the high-speed, close-tolerance machining process. The linear motors are cooled by an oil chiller to minimize thermal displacement and maintain high levels of precision. Prominent machine features include 6" x 8" work area, 0.0001" X and 0.000040" YZ axis repeatabilities and 2,000-10,000rpm spindle speed. Two control options are being offered: FANUC 18iM control with FANUC linear motors and Chevalier's own Smart control using Siemens linear motors. Easy to reach closed loop electronic control pendant features conversational programming, G-code, custom programs and options for networking. With combined speed and precision, the machine guarantees accelerated cycle times, reduced non-grinding time and increased throughput. The adjustable grinding head swivels with ±5° adjusting range to meet various grinding applications. In a test cut done on a ½" x 1" x 0.040" tungsten carbide workpiece using a diamond wheel, the machine made 35 slots 1/8" deep, 0.006" wide with a pitch error of 0.0000080" and perpendicularity of 0.00016". The entire cycle was completed in just 3 hours and 30 minutes. The machine's vertical orientation allows it to maintain a small footprint even with the full enclosure and the coolant system. The slim design also enables the operator to easily load and unload workpieces, work closer to the table and visually monitor the grinding progress. The manufacturer recommends this machine for precise, small lot work that demand high speed on very short strokes. For details about this advanced grinder, please contact Johnson Lan at Chevalier Machinery Inc., 800/243-8253. or e-mail johnsonlan@chevalierusa.com