Multi Axis Positioning Stages / Tables

Closed Loop Linear Stepper XY Stage integrates absolute encoder.

Press Release Summary:

Low-profile LSS-012-12-060-XY-01A-M integrates absolute linear encoder into single-axis linear stepper motor stage to operate linear stepper motor as 2-phase brushless linear motor when coupled with H2W motion control electronics package. Able to run in horizontal or vertical orientation, this open type positioning stage uses H2W linear stepper motors to generate 6.0 lb of force with total stroke length of 12.5 in. (each axis). Use of 1.0 micron resolution encoder fosters precise positioning.

Original Press Release:

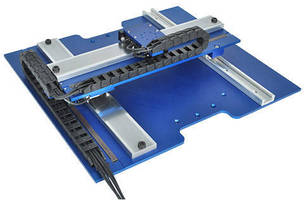

Dual Axis Closed Loop Linear Stepper Stage

The LSS-012-12-060-XY-01A-M is a revolutionary new series of low profile linear stepper XY positioning stage that integrates an absolute linear encoder into the single-axis linear stepper motor stage to operate the linear stepper motor as a 2-phase brushless linear motor, when coupled with state-of-the-art motion control electronics package provided by H2W. This allows stage to achieve speeds, accelerations, and accuracy previously unachievable with a standard open loop linear stepper motor. When operated this way, the motors will tend to run cooler as they will only draw the current needed to hold the desired position or make the desired move. Using absolute encoders removes the need to use home position sensors as the absolute position of the system will always be known, even after power is cycled. It uses H2W linear stepper motors STS-0620-R to generate a force of 6.0 lbs [26.7 N with a total stroke length of 12.5in [318mm (for each axis). The 1.0-micron (absolute) resolution encoder allows for precise positioning. Using a small intermediate plate, the top axis is able to directly mount to the moving bottom axis motor. This helps reduce the overall height and moving mass of the system. The outboard bearing adds system stability. The moving motors and encoders have high flex power cables guided by a cable carrier. Motor and encoder cables can be terminated into standard D-subminiature connectors. It has end-of-travel rubber bumper stops. There are also provisions that allow customer cables to be routed within the cable carrier. Custom mounting holes on the moving table and base are available upon request at no additional charge.

Features:

- Ability to run closed loop stepper motor (with additional electronics)

- High accuracy and repeatability

- Ability to run in horizontal or vertical orientation

- Low profile, compact, small footprint, open type, positioning stage

- Outboard bearing for stability

- Cable carriers to route system and payload cables

- Two axis of coordinated motion