Chemical Process Pump exceeds ASME (ANSI) B73.2M criteria.

Share:

Press Release Summary:

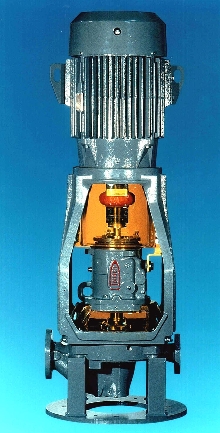

Mark III In-Line pump has SealSentry(TM) seal chambers with flow modifiers that redirect flow from circumferential to axial. Self-flushing, self-venting, and self-draining seal purges heat, solids, and vapors, thus extending seal and pump life. Pump has micrometer impeller adjustment, reverse-vane impeller, and precision motor and pump shaft alignment system for alignment within 0.002 in. ANSI 3A(TM) power frame is optional.

Original Press Release:

Flowserve Pump Division Introduces New Mark III In-Line Chemical Process Pump

Flowserve Pump Division is introducing its new Mark III In-Line Chemical Process Pump. With exclusive design features, this space-saving pump offers improved pump reliability and extended mean time between planned maintenance (MTBPM).

The Mark III In-Line Pump is designed with the unique SealSentry(TM) seal chambers including models with flow modifiers which redirect flow from circumferential to axial. This unique seal technology is self-flushing, self-venting and self-draining. Seal life is extended by this superior purging of heat, solids and vapors.

Designed to exceed ASME (ANSI) B73.2M criteria, this chemical process pump also features the Standard Mark III A power frame with micrometer impeller adjustment. This adjustment allows accurate and rapid setting of the clearance to the rear cover. Other unique features of the Mark III In-Line include:

o A reverse vane impeller for consistent high pumping performance

o Flowserve's C-Plus precision motor and pump shaft alignment system for alignment within 0.05 mm (0.002 in)

o Optional ANSI 3A(TM) power frame with three-year MTBPM guarantee.

For more information about Flowserve's new Mark III In-Line Chemical Process Pumps or any other Flowserve products contact:

Flowserve Corporation

Pump Division

4978 Riverton Rd.

Dayton, OH 45414

Telephone: (800) 728-7867

Fax: (937) 890-5314

E-Mail: fpdinfo@flowserve.com