Casting Resin is suitable for cable and harness assemblies.

Press Release Summary:

Offering alternative to injection molds when encapsulating electronics, 20-2180 Polyurethane Potting and Encapsulating Resin can be poured into metal or silicone mold to create assembly with firm seal around jacketed wires. Rubber-like texture makes it suited for outdoor applications. Resistant to moisture and chemicals, stable and vibration-resistant product has 2:1 mix ratio, self-levels around components, and will not crack. Base is natural oil polyol.

Original Press Release:

Epoxies, Etc.'s Casting Resin Great for Cable and Harness Assemblies

Consider 20-2180 as an alternative to injection molds when encapsulating electronics

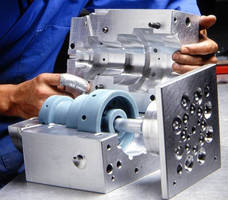

Epoxies, Etc. introduces the 20-2180, a Polyurethane Potting and Encapsulating Resin that has fitting properties for cable and harness assemblies. The 20-2180 can be poured into a metal or silicone mold to create an assembly with a firm seal around jacketed wires. Its rubber-like texture makes it ideal for outdoor applications. It is resilient and won’t crack allowing moisture to creep in.Â

Use of the 20-2180 resin in small to medium molding applications is more cost effective than the use of injection molds. The 20-2180 is stable, pours easily, and resists moisture and chemicals. It self-levels around components and cures quickly with a small amount of heat.

The 20-2180 is also great for other electronic applications, having a low viscosity, low shrinkage, and creating low stress on components. It has a convenient 2:1 mix ratio, and its base is a natural oil polyol, which is a renewable resource and low in toxicity. Go green!

For even greater ease of use, try the 20-2180 in the TriggerBond® dual barrel cartridge system – no mixing or measuring required.

Key Features:

• Sturdy yet not brittle

• Low viscosity

• Moisture and chemical resistant

• Vibration resistant

• Low shrinkage & exotherm

• Easy to use and available in TriggerBond®

• Low toxicity

Samples are available and may be requested from our website: www.epoxies.com