Castell Interlocks Safeguard Sikeston Power Station

Missouri power plant upgrades to trapped key technology

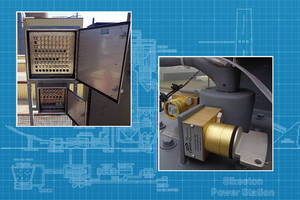

Chicago, Illinois -- Sikeston, Missouri’s Board of Municipal Utilities (BMU) recently installed trapped key interlocks from industrial safety specialist Castell throughout its 600 acre coal-fired power plant. The system limits access to dangerous areas, protecting employees from injury and equipment from damage.

Brought online in 1981, Sikeston’s 235 megawatt coal-fired steam electric generating station serves both Sikeston and numerous cities throughout the Midwest. More than a million tons of Powder River Basin coal are burned at the plant each year. The coal moves through a steady line of processing steps to the plant’s power-generating steam turbine. At each step in the process there is equipment–pulverizers, boilers, precipitators, etc.– that can be dangerous if accessed under unsafe conditions.

To prevent human error, the 30-year-old plant’s safety equipment was recently upgraded with a system of trapped key interlocks from Castell. Castell worked closely with the Sikeston BMU to select the interlock types suited to each of the processing areas. The resulting custom system ensures that proper safety precautions are taken before accessing equipment for maintenance and routine operation.

Electrical breakers, transformers and nuclear bevel detectors were fitted with Castell’s K and KF bolt interlocks to control the movement of operating handles within these panels. Only when accessed with the proper key can the bolt be retracted to change switch position. In the KF model, an additional flange increases mounting possibilities. Additionally, Castell’s AI single key access looks were installed on hopper and maintenance doors throughout the facility. A NEMA4X stainless steel enclosure manages key exchange, protecting keys from the environment.

Sikeston chose Castell products for their durable design and construction. Most of the locks are installed outside, exposed to the elements as well as fly ash from the plant. Unlike typical light duty locking devices, which can become plugged in such environments, Castell’s lock mechanism has a sealing key and cap to keep out dust and debris. This design, coupled with a large handled key, guards against failures. The key is capable of transmitting much more torque to the lock than a standard pin tumbler key for ease of operation and longevity of the interlocks.

“When looking to replace our key interlock system on the precipitator, we found the reliability, craftsmanship, support, and economic value of Castell to be the total package we hoped to achieve,” said Don Miller, Sikeston BMU’s Operations Superintendent. “We were completely satisfied with Castell and would highly recommend them for key interlocking systems.”

About Castell:

Since the inception of the industrial safety industry, Castell (www.Castell.com) has been the leader in trapped key interlocking technology, developing products that keep pace with the needs of emerging markets and applications in all business sectors. Its products go beyond meeting legislation to create the safest working environments possible. A Halma company, Castell has its US offices in Chicago, Illinois.

Castell

150 N Michigan Ave

Suite 800

Chicago IL 60601

Tel: 312-360-1516

Fax: 312-268-5174

Email: ussales@castell.com

Website: www.Castell.com

Press Contact:

Halma Holdings PR Services

Lisa Wallner

11500 Northlake Drive, Suite 306

Cincinnati, OH 45249

Tel: +1 513.326.8045

Fax: +1 513.772.5507

Email: lisa.wallner@halma.com

Website: www.halmapr.com