Capsule Filling Machine processes 2,600 capsules per minute.

Press Release Summary:

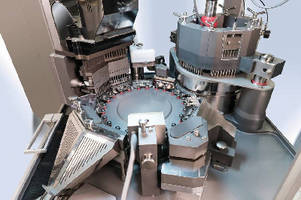

Designed to precisely dose powders, pellets, tablets, and liquids, as well as combinations, Model GKF 2600 outputs up to 156,000 capsules per hour. Micro-dosing wheel processes products in filling range of 2 –30 mg. In addition to automatic anti-troubleshooting function, system provides optimized containment with tightly sealed doors that ensure high hygiene standards are maintained during operation. Options include checkweigher, feedback loop, and inspection unit.

Original Press Release:

2,600 Capsules Per Minute: the New GKF Capsule Filling Machine from Bosch

New development according to customer requirements

High output of up to 156,000 capsules per hour

Fast process and product adaptations thanks to highly flexible machine platform

User-friendly handling at highest hygiene standards

Frankfurt/Main, Germany -- At this year's Achema, Bosch Packaging Technology, a leading supplier of process and packaging technology, launches the new capsule filling machine GKF 2600. This high-performance machine doses powders, pellet, tablets and liquids, as well as combinations precisely and reliably. An output of up to 2,600 capsules per minute can be achieved.

"The newly developed GKF 2600 combines proven and new technologies at higher outputs," Karl-Heinz Kappes, product manager at Bosch Packaging Technology, underlines. "The machine is equipped with new filling technologies for different products, an optimized drive concept, significantly enhanced sensor technology for process control, as well as a demand-oriented containment concept." Due to its extended machine platform and very good accessibility, the capsule filling machine can be adapted to fill different products in a very short time. Thanks to these characteristics, add-on modules can also be integrated quickly and easily.

New development with numerous expansion possibilities

The development of the new capsule filling machine is consistently based on the demands of the pharmaceutical industry and profits from the long-term experience of Bosch in capsule filling operations. "With its standard functions, the GKF 2600 fulfills the industry requirements regarding precise and reliable capsule filling. This includes, for instance, an automatic anti troubleshooting (ASB) function, as well as user-friendly handling with improved accessibility of the filling stations," says Kappes. The optimized containment with more tightly sealed doors further ensures that the highest hygiene standards are maintained during production.

Apart from the standard functions, numerous options are available, such as the new capsule checkweigher KKE 2600 with enhanced product control. Additionally, the GKF 2600 can be upgraded with a feedback loop, which automatically regulates overfilling and underfilling of capsules via tendency control of the KKE. An inspection unit can further be integrated into the capsule filling machine. It conducts weight and quality inspections with x-ray technology and an x-ray sensor. "Reliable micro-dosing of powders is crucial, especially for highly effective products that require an exact medication," Kappes explains.

"The micro-dosing wheel of the GKF 2600 precisely processes products in a filling range of two to 30 milligrams." Depending on customer requirements and product characteristics, the capsule filling machine can be upgraded for different containment requirements. "The combination of highly developed standard functions and versatile add-on possibilities makes the GKF 2600 a future-proof solution for a broader product spectrum," Kappes concludes.

Bosch's technologies are on display at Achema in Frankfurt/Main, Germany, from June 15 to 19, hall 3.1, booth C71.

Contact:

Karl-Heinz Kappes

phone: +49 711 811-57255

Contact person for press inquiries:

Christin Poenisch

phone: +49 711 811-58502

Based in Waiblingen near Stuttgart, Germany, and employing 5,600 associates, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology. At over 30 locations in more than 15 countries worldwide, a highly-qualified workforce develops and produces complete solutions for the pharmaceuticals, food, and confectionery industries. These solutions are complemented by a comprehensive after-sales service portfolio. A global service and sales network provides customers with local points of contact. Additional information is available online at www.boschpackaging.com

The Bosch Group is a leading global supplier of technology and services. According to preliminary figures, its roughly 290,000 associates generated sales of 48.9 billion euros in 2014. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. The Bosch Group comprises Robert Bosch GmbH and its more than 360 subsidiaries and regional companies in some 50 countries. If its sales and service partners are included, then Bosch is represented in roughly 150 countries. This worldwide development, manufacturing, and sales network is the foundation for further growth. In 2014, Bosch applied for some 4,600 patents worldwide. The Bosch Group's strategic goal is to deliver innovations for connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm.

In short, Bosch creates technology that is "Invented for life."

Additional information is available online at www.bosch.com, www.bosch-press.com, http://twitter.com/BoschPresse