CAM Software supports high-speed and 5-axis machining.

Share:

Press Release Summary:

PowerMILL CAM 2015 provides vortex area-clearance strategy that produces safe toolpaths with deep cut while enabling accelerated feed and material removal rates. Cutting is undertaken at consistent volume-removal rate and at near constant feedrate to extend tool life and protect machine. Other features include collision checking, raster finishing, curve-creation options, and roughing algorithm that reduces number of lifts per toolpath slice.

Original Press Release:

Delcam to Launch PowerMILL 2015 for High-Speed and Five-Axis Machining at IMTS

Delcam will launch the 2015 version of its PowerMILL CAM system for high-speed and five-axis machining at IMTS 2014 in Chicago from 8th to 13th September on booth E3222, the largest CAM software booth at the show. The new release will include improvements to the Vortex high-efficiency area-clearance strategy, improved collision checking to also cover near misses, and more efficient raster finishing.

For more information on PowerMILL, please go to www.powermill.com

The Vortex area-clearance strategy produces safe toolpaths with a much deeper cut by using a controlled engagement angle that maintains the optimum cutting conditions for the whole toolpath. As a result, higher feed rates and material-removal rates are possible, making the cutting time shorter by as much as 70%. In addition, cutting is undertaken at a more consistent volume-removal rate and at a near constant feedrate, so extending tool life and protecting the machine.

Two enhancements in PowerMILL 2015 will give even greater reductions in machining time compared to conventional roughing. The first change allows toolpaths to approach the part from outside the stock at the cutting height for open pockets or in areas where earlier cuts have made this possible. Previously, all entry moves had to be made by plunging onto the surface or by ramping into the material.

The second change allows an increased feed rate to be set for non-cutting moves. The default value is set at double the rate for the cutting moves but this can be altered as required for each machine tool. The extra time that can be saved depends on the shape of the part but an additional saving of around 20% should be expected above the earlier releases of Vortex.

Another problem in previous versions of PowerMILL was that unnecessary lifts could be added to area-clearance toolpaths when the cutter moved outside the stock or close to its edge. Changes to the roughing algorithm have now reduced the number of lifts per toolpath slice to the minimum needed and so made area clearance much more efficient.

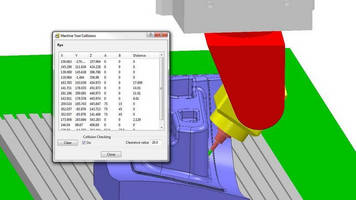

Companies using PowerMILL for either positional or continuous five-axis machining will benefit from improvements to the collision checking within the software. Firstly, collision checking has been changed so that warnings can also be flagged for near misses. The user can now specify a clearance value and when the machine tool comes within this value it will turn yellow in colour to highlight a near miss. Collisions will still be shown by a change of colour to red.

Secondly, the display showing the list of collisions, and now near misses as well, has been updated to be easier to read, making it simpler to extrapolate the coordinates at these points. For near misses, the clearance distance is shown in the display, with the distance shown as zero for collisions.

Another improvement will help companies using four- or five-axis machines with trunnions or similar tilting tables. Previous PowerMILL toolpaths could exhibit unwanted changes of azimuth as the cutting tool approached a position vertical to the part. This would slow down the machine, often to the extent that a witness mark would be left on the surface. New options are now available to specify the information used by PowerMILL to distribute the toolpath points so that the machine’s gimbal-lock position is avoided and a smoother motion results.

Raster finishing has also been improved in PowerMILL 2015, with the software now able to set automatically the most appropriate angle for each region of the part. In previous versions, the user had to select each area and specify the angle manually. The new option, which provides the same functionality that already existed for steep-and-shallow finishing and face milling, is most beneficial when finishing a series of pockets aligned in different directions.

A number of improvements have been made to the PowerMILL interface. Most important is a clearer form for the strategy selector that makes navigation easier when choosing which strategy to use. It has also been made easier to create folders of strategies, for example, those most suitable for a particular machine tool, material or type of part, and to add and remove strategies from those folders.

Finally, three new curve-creation options have been added to the curve editor – ellipse, spiral and helix. These options can be used to create patterns or boundaries when generating toolpaths.

For further information on Delcam’s PowerMILL CAM software, please contact: -

Peter Dickin

Marketing Manager

Direct phone: 0121 683 1081Â

e-mail: marketing@delcam.com

Delcam Ltd

Small Heath Business Park

Birmingham, B10 0HJ, UK

www.delcam.com