CAM Software supports definition of complex profiles.

Press Release Summary:

SmartCAM® v2014 products comprise CAM applications for CNC milling, turning, fabrication, and wire EDM. While UI aids use via panel task menus, customizable toolbars, and screen configuration options, features also include support for multiple Undo/Redo operations for all modeling tasks. Milling process capabilities increase toolpath reliability and efficiency while reducing number of required steps, and connections in Facing and Region Rough processes provide high-speed machining technique.

Original Press Release:

SmartCAM V2014 Released

Redesigned User Interface Highlighted

New Undo System, Milling, Verification Improvements Also Added

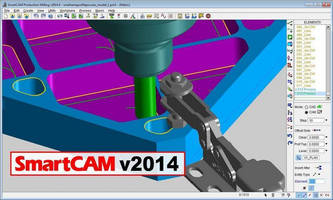

SPRINGFIELD, OREGON – SmartCAMcnc has announced the release of SmartCAM® v2014. SmartCAM v2014 delivers a redesigned and improved user interface that assists in usability, ease of learning and user efficiency, plus a variety of milling process modeling, toolpath verification and geometry modeling improvements.

The SmartCAM product family consists of Computer-Aided Manufacturing (CAM) applications for Computer-Numerical Control (CNC) milling, turning, fabrication and wire EDM.

SmartCAM v2014 introduces extensive user interface updates that give the product a more modern look and feel while also making it easier to learn and use. New panel task menus and customizable toolbars make it more convenient to access frequently used commands, and new configuration options allow the system to be tailored to make best use of screen workspace.

Additionally, the SmartCAM Undo mechanism has been completely re-written to allow multiple Undo or Redo of all modeling tasks, a significant advantage over previous versions.

"SmartCAM v2014 users will first notice the new user interface which is a logical evolution of the familiar SmartCAM modeling environment." said Douglas Oliver, SmartCAMcnc’s Senior Product Manager. "The new task bar menus, coupled with the ability to configure custom toolbars provide users extremely quick and convenient access to their most-commonly used tasks, substantially improving efficiency and productivity."

"And of course the new Undo allows users the flexibility to try various machining strategies with the ability to quickly revert to a prior model state," Oliver went on to say. "That is a huge improvement that every user will enjoy."

Improvements to the milling processes increase toolpath reliability and efficiency, and reduce the number of steps required to re-machine remaining material and generate wireframe profiling toolpath. New arc connections in SmartCAM's Facing and Region Rough processes provide a "high-speed machining" technique that prevents abrupt direction changes which may be potentially harmful to machinery.

The ShowCut and ShowPath toolpath verification modules have been enhanced to make better use of standard tooling by providing improved visualization of turning-tool holders, and allowing milling-tool holders to be used with parametrically defined tools. New collision reporting and holder checking capabilities assists users in finding potential problems.

SmartCAM v2014 also boasts a number of significant improvements to SmartCAM's modeling capabilities. These improvements make it easier to define complex profiles using limited dimensional data, or by performing Boolean modeling operations on multiple closed boundaries.

All SmartCAM v2014 products will benefit from an updated ACIS® modeling kernel as well as updated native and generic data translators.

"The hallmark of SmartCAM is the Toolpath Modeling that allows CAM toolpath to be created in the same way as CAD geometry. But getting across the concept of Toolpath Modeling to new users has proven sometimes difficult", added Oliver. "The user interface improvements in SmartCAM v2014 help new users grasp Toolpath Modeling much more quickly while at the same time making the daily use by existing users more direct and efficient."

About SmartCAM & SmartCAMcnc

The SmartCAM family of computer-aided manufacturing software provides toolpath modeling and CNC programming for prismatic production work to complex molds, dies, and prototypes. SmartCAMcnc provides affordable maintenance contracts, updates, upgrades and technical support for all SmartCAM users, regardless of version. All SmartCAM products include updated data translators and market-leading NC editing software from Predator Software, Inc (www.predator-software.com).

SmartCAMcnc is a Springfield, Oregon-based company that was established in December 2003 to develop, sell and support SmartCAM for the benefit of its worldwide customer base of over 12,000 companies in 63 countries. The company has successfully delivered at least two major releases of the award winning software each year since then.

To monitor further developments please visit www.SmartCAMcnc.com.