CAM Software adds tombstone machining capabilities to SolidWorks.

Share:

Press Release Summary:

Fully integrated into SolidWorks environment, Delcam for SolidWorks 2014 R2 is based on Delcam machining algorithms and combines benefits associated with Delcam PowerMILL and FeatureCAM CAM systems. Module provides support for tombstone machining, and various options are available for stock models. Other features include support for holes from SolidWorks Hole Wizard, flexible Z-level roughing, accelerated toolpath calculation, and knowledge-based automation.

Original Press Release:

Delcam for SolidWorks Adds Tombstone Machining and More

A new module has been added to Delcam for SolidWorks, Delcam’s fully-integrated CAM system for SolidWorks, so that the software can now support tombstone machining. Other enhancements in the 2014 R2 version include new options for stock models, better support for holes from the SolidWorks Hole Wizard and more flexible Z-level roughing.

For full details, including video demonstrations of the new functionality, and to download the free Delcam for SolidWorks XPRESS version for 2D milling and drilling, please go to http://lz.delcamforsolidworks.com .

Delcam for SolidWorks combines the benefits associated with Delcam’s PowerMILL and FeatureCAM CAM systems. It is based on Delcam’s proven machining algorithms that are already used by more than 40,000 customers around the world. The software offers PowerMILL’s exceptional speed of toolpath calculation, plus the advanced strategies for high-speed and five-axis machining, to ensure increased productivity, maximum tool life and immaculate surface finish, even when cutting the hardest, most challenging materials. At the same time, Delcam for SolidWorks has the same strong focus on ease of use as FeatureCAM, including all of the knowledge-based automation that makes that system so consistent and reliable.

Delcam for SolidWorks is fully integrated into the SolidWorks environment so that the program looks and behaves like SolidWorks. It offers full associativity so that any changes in the CAD model are reflected automatically in the toolpaths. However, this associativity is more intelligent than that offered in many other integrated CAM systems. Delcam for SolidWorks doesn’t simply modify the existing toolpaths but also reviews the choice of cutting tools and machining strategies, and changes them if necessary.

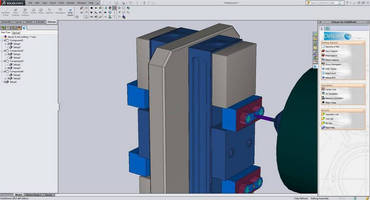

Tombstone machining allows multiple parts to be loaded onto different sides of a fixture and then machined in one sequence. The fixture and the complete set of parts can then be replaced, in some cases automatically, with the next set of components and the associated tombstone. With the new tombstone-machining module, parts that have been programmed individually can be positioned around the tombstone and a single program generated for the complete set. Models of the tombstone and any other fixtures can be loaded into the assembly within the software and are then treated in the same way as other fixtures. The NC code can be generated either relative to the set-ups of individual models or relative to reference set-ups within the tombstone assembly.

In a related development, Delcam for SolidWorks now also supports multiple, simultaneous part comparisons. If a set of different parts is being machined on a tombstone, or any other fixture, the various components can be verified with their respective CAD models in one operation.

Rough machining in Delcam for SolidWorks 2014 R2 has been improved with a new option to set the direction in which Z-level roughing toolpaths are offset. A simple button allows the user to select whether the part should be machined from the outside inwards or from the inside towards the outside. An automatic option can also be chosen where the software will decide the offset direction, depending on whether a core or a cavity shape is being machined.

A number of improvements have been made to the stock model functionality in Delcam for SolidWorks. The first of these enhancements eliminates excessive tool engagement and limits the maximum depth of any cut into un-machined material. Both these controls reduce tool wear and improve surface finish by avoiding any overloading of the tool. The same functionality also removes toolpath segments that machine very little or no material.

Rest machining has been made more efficient in two ways. Firstly, a new “detect metal thicker” command ensures that rest material thinner than the specified limit is ignored. This prevents toolpaths being generated in any areas where the benefit of the extra cut is negligible, such as cusps left by the previous toolpath.

Secondly, toolpath fragmentation and the resultant air moves between fragments can be reduced by specifying a minimum gap length between cutting moves. Any gaps shorter than the specified distance will be linked with a tangential move between the segments, rather than having the tool retract fully from the surface for a very short air move.

In addition, new functionality has been added that allows stock models to be modified by removing operations. This eliminates the need in previous releases to recreate the stock model completely if such a change was needed.

Finally, Delcam for SolidWorks offers better support for hole manufacture by recognising dowel holes as reamed holes. During programming, the software will select automatically the appropriate drill and reamer to be used in the program for the size of the hole.

The cutter compensation used by Delcam for SolidWorks can now be specified on an operation level so removing the need to create duplicate features in order to set different values. The most common case where this will be needed is when different cutter compensation is required for the finish pass and for any subsequent chamfering operation.

For further information on Delcam for SolidWorks, please contact:

Peter Dickin, Marketing Manager

Direct phone: 44 (0)121 683 1081Â

e-mail: marketing@delcam.com

Delcam plc

Small Heath Business Park,

Birmingham, B10 0HJ, UK

www.delcam.com