CAD/CAM Software includes feature exchange technology.

Press Release Summary:

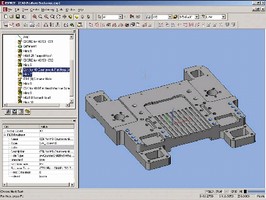

ESPRIT 2007 with ESPRIT FX(TM) technology provides portions of original CAD Feature Tree directly inside ESPRIT user interface, thereby including original design intent. CAD features and associated properties are mapped into machinable features providing complete definition of what is being machined. Manufacturing properties are then fed into ESPRIT KnowledgeBase, which aids user in selecting how to machine part based upon existing best practices.

Original Press Release:

ESPRIT 2007 Introduces the All-New ESPRIT FX - Feature eXchange- Technology

Camarillo, Calif.-June XX, 2006- ESPRIT FX(TM) is the latest in CAD to CAM feature exchange technology, included in ESPRIT 2007, which allows users to automatically capture the original design intent, clearly define what the user is machining, and program parts quicker and more accurately.

Going beyond transferring just the part geometry, the FX(TM) technology provides portions of the original CAD Feature Tree directly inside the ESPRIT user interface thereby including the complete original design intent - features, tolerances, material properties, surface finishes, administrative data, etc. Using the FX(TM) technology the CAD features and their associated properties are mapped into machinable features

providing a complete definition of 'what' is being machined. These manufacturing features and their properties are then fed into the ESPRIT KnowledgeBase which aids the user in automatically selecting how to machine the part based upon existing best practices.

ESPRIT FX(TM) Milling

Within ESPRIT 2007, the FX technology applied to milling allows users to now easily distinguish between the type of a given feature. As an example, a Solid model may contain a hole, but the Solid model itself provides no definition in regards to the type of hole or tolerances to be applied. Using the FX technology, which provides access to the original CAD feature tree, one can automatically distinguish between hole types and determine such things as thread pitches and tolerances, which are required in order to determine the correct machining processes. The feature name and feature description, made available by the ESPRIT FX technology, are also commonly used to understand what is being machined thereby simplifying the selection of the optimal machining process(es), With the use of FX technology one can now automatically determine exactly what a given feature represents and how it should be machined.

ESPRIT FX(TM) Wire EDM

Using the ESPRIT 2007 FX(TM) technology for EDM programming automates the process of determining how a part should be cut- 2-axis or 4-axis. FX technology allows ESPRIT 2007 to automatically map one or more CAD features into one or more machineable features. This mapping is performed in part based on both the geometric shape on the Solid model and upon the properties associated to each selected CAD feature. The feature type, name, and description are mapped from the CAD feature to the machineable feature(s) which allows the ESPRIT KnowledgeBase to automatically select the most appropriate machining process based upon existing best practices.

ESRPIT FX(TM) Availability

ESPRIT FX will begin shipping with ESPRIT 2007 to all new and existing ESPRIT customers. Native support is planned for all six major Solids based CAD systems Catia, Inventor, Pro Engineer, Solid Edge, SolidWorks, and Unigraphics. Additionally, the ESPRIT FX technology is exposed through the ESPRIT Applications Programming Interface (API) and through the use of ESPRIT's built-in Visual Basic capabilities; ESPRIT programmers now have access to this technology from their Visual Basic macros.

About ESPRIT

ESPRIT is a high-performance computer-aided manufacturing (CAM) system for a full range of machine tool applications. ESPRIT delivers powerful full-spectrum programming for 2-5 axis milling, 2-22 axis turning, 2-5 axis wire EDM, multitasking mill-turn machining, and B-axis machine tools.

About DP Technology Corp.

DP Technology is a computer-aided manufacturing (CAM) software market leader with a mission to provide CNC programmers with the most powerful CAM software ever. DP Technology's flagship product, ESPRIT, captures the company's vision of technology's potential and its passion for excellence.

DP Technology maintains its worldwide headquarters in Camarillo, California and product development teams in California and Florence, Italy. Sales and support operations are located in Europe, Asia, and North and South America. For additional information about DP Technology and ESPRIT, call +1-805-388-6000, send an email to esprit@dptechnology.com, or visit the company web site at www.dptechnology.com.