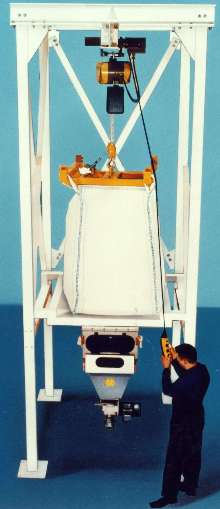

Bulk Bag Discharger incorporates hoist for bag unloading.

Press Release Summary:

Type 6 Bulk Bag Discharger allows single operator to control 1 ton hoist, which positions bulk bag over discharge dish for processing, eliminating need for full time forklifts. Designed to customer specifications, unit is offered in carbon steel and 304 stainless steel designs with I-beam construction. Discharger has bag-tensioning frame, which monitors capacity/weight of bag and stretches it to ensure no material waste.

Original Press Release:

Spiroflow Systems Introduces Innovative Hoist Bulk Bag Discharger Design

CHARLOTTE, NORTH CAROLINA---Spiroflow Systems, Inc. announces an innovative "Hoist Design" Bulk Bag Discharger for unloading bulk bags without the use of a full time forklift.

Spiroflow's new Type 6 Bulk Bag Discharger (BBD) is used for unloading powder or granular product material into various other processing equipment including flexible screw, rigid screw, pneumatic, and mechanical conveyors. The unit is designed to allow one operator to control a standard 1-ton hoist which positions the bulk bag over the discharge dish for easy processing.

The Type 6 BBD is designed to customer specifications. Each Type 6 is engineered with a standard 1-ton hoist and is available in carbon steel and 304 stainless steel designs. The unique "I" beam construction guarantees a worry-free discharging station, since the lifting frames are fully load tested and are available to suit existing hoist systems. The Discharger touts an innovative bag tensioning frame which monitors the capacity/weight of the bag and stretches it to ensure no material waste. Side and bottom pneumatic massage bottoms are also available to promote product flow.

Each discharger also has a standard chute with integral locking access door and viewing port. The door is amply sized for the operator to manipulate the bag spout and liner.

A number of other options are available including a patented "Y" bar bag neck closure system, which pneumatically closes the bag neck for easy retying of the bag for reuse or for safety concerns while the operator manipulates the bag spout. Other features available include NEMA-7 level probes; loss-in-weight load cells, motorized trolley for hoist, and an integral bag dump station.

Spiroflow is a worldwide supplier of a wide range of both standard and custom powder handling equipment, specializing in Bulk Bag Dischargers and Fillers, Mechanical, Flexible, and Pneumatic Conveyors, and Bag Packing equipment.

For more information about Spiroflow Bulk Bag Dischargers or other powder handling equipment, telephone 704-291-9595, fax 704-291-9594 or email info@spiroflowsystems.com. Spiroflow can also be found on the Internet at www.spiroflowsystems.com.