Booth Filling System protects operators from fumes.

Share:

Press Release Summary:

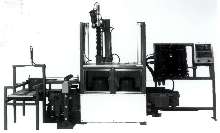

Filling system features totally enclosed filling operation and fume removal. Instrumentation and controls are located in separate area, while removable panels permit access to parts and simplify maintenance. System handles containers from 5 gal pails to IBCs and can fill up to three 5 gal pails or one 55 gal drum per minute. Product includes PC 104-based digital weightmeter with display and operator-prompting.

Original Press Release:

New Booth Filling System Protects Operators from Fumes and Heated Products

A new filling system, designed to shield personnel from product fumes and super-heated products, has been introduced by Velcon Fillers of Freeport, Texas.

This new filling system features totally enclosed filling operations and fume removal, with the system's instrumentation and controls located in a separate area. Removable panels permit easy access to parts and simplify maintenance.

The system can be modified to handle containers ranging in size from 5-gallon pails to intermediate bulk containers (IBC's). It can fill up to three 5-gallon pails or an entire 55-gallon drum per minute.

Standard construction material for all Velcon Fillers is 304 stainless steel. Fillers are also available in other materials, such as plastic and epoxy-coated carbon steel for applications where stainless steel is undesirable. A PC 104-based digital weightmeter with easy-to-read display and operator-prompting is included as standard equipment. Additional standard equipment includes a drip pan, a wiper ring, data logging and many software enhancements.

For more information on the new Booth Filling System, contact David Youngmeyer at Velcon Fillers, 202 S. Ave. A, Freeport, Texas 77541. Telephone 800/619-4784, ext. 137. Fax 979/233-0140. Email: sales@velconfillers.com Web: velconflflers.com