BKG® HiCut™ Cutter Hub Now Accommodates both Angled and Straight Blades

Press Release Summary:

BKG® HiCut™ Cutter Hub is designed for BKG® underwater pelletizers which increase the working life and lifespan. The new hub design increased the number of blades by form factor of 50%, throughput and reduction in pelletizer RPM. The hub features round edges and smooth surfaces with countersunk screws, which reduces swirling and optimizes the flow. HiCut™ Cutter Hub improves lifespan of the blades when used on non-abrasive compounds.

Original Press Release:

New Cutter Hub for Pelletizing Enables Bischof + Klein to Use Blades Much Longer and to Improve Pellet Quality

BKG® HiCut™ Cutter Hub from Nordson Tripled Working Life of Blades, and with Non-Abrasive Materials Increased the Lifespan from 3 Days to Nearly 3 Weeks

LENGERICH, GERMANY, April 9, 2018: Bischof + Klein, a leading European producer of films and laminates, reports that new-design cutter hubs retrofitted on its pelletizers have substantially increased blade life and improved pellet quality. Nordson Corporation will introduce the cutter hub design at NPE2018 (Booth W2525).

Bischof-Klein uses BKG® underwater pelletizers from Nordson Corporation within their compounding lines to mix colors and additives for its film manufacturing. When the company installed Nordson’s new BKG® HiCut™ cutter hubs on two of its pelletizing lines, the blades mounted on the hubs lasted two to three times longer than those of the older design, and with some materials—particularly non-abrasive compounds—blade life was extended from a typical three days to nearly three weeks. In addition, the pellets produced with the blades exhibited fewer “tails,” which subsequently separate from the pellet as fines, can abrade or clog equipment, and represent a waste of polymer.

“Because Nordson’s new design increased the number of blades on the hub by a factor of 50%, we were able to reduce the rotation speed of the cutter while maintaining our standard high level of throughput,” said Eduard Beifus, responsible for regenerates and concentrates at the Bischof + Klein site in Lengerich, Germany. “This decrease in driving speed led to a reduction in wear to the blades and a substantial increase in their lifespan.”

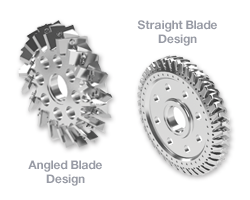

In an underwater pelletizer, polymer strands emerge from the die plate, solidify as they enter the water, and are then cut into pellets by the blades mounted on the cutter hub. The new HiCut design accommodates up to 100% more angled blades per hub and up to 54% more straight blades. This makes possible an increase in throughput or, alternatively, a reduction in pelletizer RPM, which decreases wear to the die plate and blades.

“The blades on BKG HiCut cutter hubs have round edges and smooth surfaces with countersunk screws. This optimizes the flow and reduces swirling, and there is more space between the blades so that pellets do not accumulate,” said Frank Asmuss, global product manager for BKG pelletizing systems. “For certain products, the increased throughput achieved with the new design makes it possible to invest in a smaller pelletizer, saving cost.”

BKG HiCut designs are compatible with all existing pelletizer systems, and the hub accommodates both angled and straight blades.

Bischof + Klein SE & Co. KG is one of Europe's leading full-service suppliers of flexible plastic and plastic laminate packaging and technical films. Its product range encompasses traditional industrial packaging, highly converted consumer packaging, and innovative special films for technical applications. This year, the family-owned company with 2,600 employees celebrates its 125th anniversary. Email: info@bk-international.com. Visit https://www.bk-international.com/de_en/.

Nordson Corporation engineers, manufactures and markets differentiated products and systems used for the precision dispensing of adhesives, coatings, sealants, biomaterials, polymers, plastics and other materials, fluid management, test and inspection, UV curing and plasma surface treatment, all supported by application expertise and direct global sales and service. Nordson serves a wide variety of consumer non-durable, durable and technology end markets including packaging, nonwovens, electronics, medical, appliances, energy, transportation, construction, and general product assembly and finishing. Founded in 1954 and headquartered in Westlake, Ohio, the company has operations and support offices in more than 30 countries. Visit Nordson on the web at http://www.nordson.com, @Nordson_Corp, or www.facebook.com/nordson.

Nordson Polymer Processing Systems provides customers with engineered components to melt, homogenize, filter, meter, and give shape to plastic and fluid coating materials. Nordson Corporation leverages the collective plastics industry experience from a series of strategic acquisitions to offer a uniquely broad portfolio of industry-leading technologies. Nordson delivers a full range of precision melt stream products — from screws and barrels for extrusion and injection molding — to filtration systems, pumps, and valves — to the extrusion dies and pelletizing systems to meet the constantly evolving needs of the polymer industry.

Nordson Corporation provides customers with local technical sales, service and remanufacturing capabilities through sales organizations and regional manufacturing facilities in over 30 countries. To learn more visit us at http://www.nordsonpolymerprocessing.com or www.facebook.com/NordsonPPS.

Robert J. Martino

Martino Communications Inc.

Tel: 1-203-321-0787

Email: bob@martinocommunications.com