Benchtop SPI System offers 17 cm²/sec measurement speeds.

Press Release Summary:

Solder paste inspection (SPI) system, A500, automatically finds fiducials, identifies pads, and files height and volume data for each pad. Color-coded pads on Gerber data show pads outside thresholds in real-time, and historical data for board is also readily available. By zooming into Gerber data, users can explore 3D views of pads. XY motion allows scanning of PCB panels up to 300 x 300 mm, and Z-axis motion allows for auto-focus of sensor and board warpage compensation.

Original Press Release:

VisionMaster Changes the Game with New Benchtop SPI System

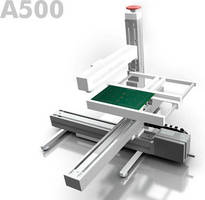

PORTLAND, MAINEÂ – VisionMaster, Inc., a leading manufacturer of advanced 3-D solder paste inspection (SPI) and measurement equipment, introduces A500, the best benchtop SPI system in world. Fully automatic, the system is set-and-forget SPI for monitoring and tweaking your solder paste printing process.

The A500 is unbelievably easy-to-use. Simply open a Gerber file and select the components that need to be measured by dragging the mouse. With a single click, the system takes over, automatically finding fiducials, identifying pads and filing away height and volume data for each pad. Color-coded pads on the Gerber data show pads outside the thresholds in real-time. Historical data for the board is available at your fingertips by sliding a simple bar back-and-forth. By zooming into the Gerber data, users can swoop into 3-D views of the pads. Data is presented in intuitive “exploding” charts for SPC. SPI data presentation does not get any more intuitive.

With measurement speeds up to 17 cm²/sec, a typical board can be 100 percent inspected in less than 30 seconds. This speed is achieved with an amazingly high lateral resolution and accuracy.

The A500 is completely plug-and-play with any Windows™ 7 computer that has a Gigabit Ethernet port. The A500 is low maintenance and is designed to provide years of trouble-free usage. The sensor and mounting components are machined from aircraft grade aluminum. To ensure consistent high quality, more than 95 percent of sensor and power supply components are sourced within the United States, and the motion system is sourced from Japan.

State-of-the-art XY motion allows totally automatic and seamless scanning of PCB panels up to 300 x 300 mm. The Z-axis motion allows for auto-focus of the sensor and board warpage compensation. The A500X uses a laser stripe that keeps the board in focus in real-time independent of the 3-D data acquisition.

As with all other VisionMaster equipment, the A500 uses advanced white light and infra-red structured light scanning to build height data for every pixel in the view. Long life, solid-state LEDs are used for projection and background lighting. Advanced CMOS image sensors are immune to electrical analog noise, resulting in very repeatable measurements. Gigabit connectivity means fast, reliable and easy connection to the PC.

“We, at VisionMaster, are proud to introduce our game-changing fully automatic A500 systems. VisionMaster has the best price:performance ratio in SPI. The awesome A500 starts at an awesomely low $28,999. Contact us to find out how VisionMaster can solve your inspection problems today,” said Allegra McNeally, Vice President, VisionMaster.

For more information, visit www.visionmasterinc.com.

About VisionMaster

Established in 1996, VisionMaster is a privately held company that focuses on the most efficient, effective engineering to ensure the highest quality products. Focusing on R&D, VisionMaster has made strategic investments so that the company has the capacity to create custom components, which results in superior specs while lowering its – and it customers’ – costs. Every aspect of the M500 and A500 has been completely re-engineered and the results show it. For more information, visit www.visionmasterinc.com.