Belt-Driven Boom positions robots and gantries.

Press Release Summary:

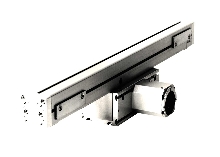

DGEA toothed-belt-driven electric boom-arm axis is suitable for positioning applications requiring horizontal or vertical projecting motions. Fixed pinion drive mechanism engages stationary toothed belt, causing projecting structure to traverse work envelope. Roller guide bearing system is integrated into housing. Unit has stroke range of 100-1,000 mm, payload of 110 lb, speed of 2.1 m/sec, and is available in 3 sizes of 18, 25 and 40mm.

Original Press Release:

Motorized Precision Belt-Driven Axis Augments Festo's Positioning Technology

The DGEA toothed-belt driven electric boom-arm axis expands Festo's modular positioning system technology to better measure up to the demands of precision Cartesian robot and gantry applications. This unit is designed especially for positioning applications requiring horizontal or vertical projecting motions, since the integral motor-driven carriage ensures minimum displaced mass and maximum dynamic response for short cycle times.

This new addition to Festo's motorized linear axis family (Type DGE) offers a stroke range between 100 to 1000 mm and maximum payload of up to 50 kg (110 lbs.) It is available in three sizes (18, 25 and 40mm). Installation of the DGEA unit is simplified by the carefully designed interfaces for power and position control cabling.

The DGEA is designed to perform projecting motions, as the pinion drive mechanism is fixed, and engages a stationary toothed belt, causing the projecting structure to traverse the work envelope. The flat design of the drive head brings a decisive improvement with respect to oscillation characteristics. A roller guide bearing system is integrated into the housing and ensures precise motion at a maximum speed of 2.1 meters per second, while at the same time protecting the DGEA drive from contamination. When ordered for vertical applications, the DGEA is available with a motor brake system integrated in the drive package.

The DGEA is a capable addition to Festo's modular positioning system (Type DGE), since it is highly compatible with Pick & Place gantry applications, or any configuration supported by the system's comprehensive list of mounting accessories and mechanical interfaces. The accessories and interfaces facilitate the integration of all 300 components of Festo's modular system for handling and assembly technology.