Beckhoff to Debut New Automation Solutions for Smart Intralogistics at MODEX 2020

North American introduction of Beckhoff alternative OS, machine controller and motion control systems will be highlight innovations

SAVAGE, Minnesota, February 3, 2020 – During MODEX 2020, Beckhoff Automation will present automation technologies for wide-ranging material handling and intralogistics applications from March 9 – 12 at the Georgia World Congress Center in Atlanta. The smart distribution center solutions will include the North American debuts of the EP7402 controller for motor-driven roller (MDR) conveyors, TwinCAT/BSD alternative operating system (OS) for Beckhoff PC-based controllers and C6025 ultra-compact Industrial PC (IPC). The eXtended Transport System (XTS) will also make its MODEX debut at the Beckhoff booth (4026).

Intelligent motion control for dynamic product transport

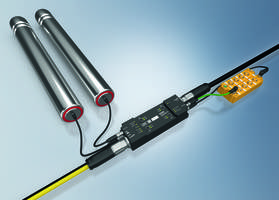

Beckhoff will launch a compact motion control solution for intralogistics: the EP7402 MDR controller. The IP67-rated EtherCAT Box module controls motors on roller conveying systems with multiple zones. Measuring just 174 mm x 60 mm x 36.5 mm, the MDR controller can dramatically reduce equipment footprint and help minimize warehouse space requirements.

The EP7402 also simplifies wiring using the EtherCAT P standard: a B23 hybrid connection combines EtherCAT communication with 24 V DC at 30A to support up to 16 MDR controllers before refreshing power. The solution supports the integration of TwinSAFE, the Safety over EtherCAT (FSoE) solution from Beckhoff, in the same architecture. The MDR controller offers traditional conveyors the high performance, space savings and scalability inherent in motion control components from Beckhoff, including the AMP8000 Distributed Servo System and AX8000 Servo Drives.

For optimum flexibility, the XTS, a revolutionary linear transport solution from Beckhoff, moves products individually with high dynamics and speeds. The modular system optimizes high-speed material handling applications that require clamping and moving products, integration with robotics in real-time via EtherCAT and gapping and synchronization of product flows. XTS movers ensure maximum traceability from pick to drop. Changeovers occur instantly via TwinCAT to enhance ever-changing fulfillment centers.

TwinCAT/BSD: a powerful alternative OS for Beckhoff controllers

A key update for the flexible PC-based automation platform is the introduction of TwinCAT/BSD as an alternative OS for Beckhoff controllers. Ideal for intralogistics, TwinCAT/BSD combines the TwinCAT realtime with FreeBSD — an open-source, highly secure, Unix-based operating system used by industrial and consumer technology vendors. Many Linux applications used in intralogistics can easily be ported to this OS, including execution of native Linux binaries. This affords greater customization, reduced license costs and ease of distribution with third-party vendors. Engineering in Visual Studio® still occurs on standard Windows PCs or via web browsers using TwinCAT Cloud Engineering, and support of Windows-based systems will continue.

Integrated image processing and speech in TwinCAT

Also on display will be TwinCAT Vision software, an integrated image processing solution that enables Industrie 4.0 concepts, real-time synchronization, track-and-trace and quality optimization. TwinCAT Vision leverages the benefits of GigE cameras on diverse machines and lines without requiring separate, third-party vision systems or programming by outside experts. The universal TwinCAT engineering environment and runtime permit vision system programming and implementation using languages familiar to controls engineers.

Increasing its IoT and smart distribution center offerings, Beckhoff will display TwinCAT Analytics and HTML5-enabled TwinCAT HMI for industrial displays and mobile devices. In addition, Beckhoff will showcase how TwinCAT Speech can streamline order picking with fulfilment systems and AGVs. With these fully integrated solutions, TwinCAT offers an end-to-end software platform complete with PLC, motion control, robotics, high-end measurement technology and machine learning that is perfectly suited to material handling.

For PC-based control hardware, the C60xx ultra-compact IPC line will return with the C6025. This fanless machine controller boasts new Intel® Core™ i U processors and measures 82 x 127 x 40 mm. C6025 extends the Microsoft Azure-certified family of Beckhoff IPCs that encompasses the C6015 to C6032, which are all suited for mid-range to complex machine control, vision applications and as edge computing or IoT gateway devices to all major cloud platforms, including Amazon Web Services (AWS).

EtherCAT offers Gigabit communication and safety

To boost data throughput in today’s distribution centers, Beckhoff has combined the fundamental principles of EtherCAT with Gigabit speeds. EtherCAT G and EtherCAT G10 extend standard EtherCAT to communication rates of 1 Gbit/s and 10 Gbit/s, respectively, while conforming with the IEEE 802.3 Ethernet standard. An innovative branch controller model enables parallel operation of standard 100 Mbit/s segments with Gigabit branches. This expands the system that already includes countless I/O modules, including IP67 and IP69K form factors, and integrated functional safety.

“The flexible, open automation platform from Beckhoff offers the perfect solution to help distribution and fulfillment centers keep pace with e-commerce demands and accelerate digital transformation,” said Doug Schuchart, material handling & intralogistics manager, Beckhoff Automation LLC. “Not least among these innovations are the EtherCAT industrial Ethernet system and the IoT capabilities of TwinCAT. However, Beckhoff has demonstrated its commitment specifically to the intralogistics industry with the release of the EP7402 MDR controller, the product transport benefits of XTS and other key innovations on display at MODEX 2020.”

Beckhoff at MODEX 2020

Beckhoff Automation is a provider of advanced and open automation solutions based upon proven technologies for customers to implement high-performance control systems faster and at a lower overall cost than traditional PLC and motion control systems. Beckhoff’s “New Automation Technology” product range includes PC-based control, industrial PCs, automation controllers, operator interfaces, I/O, servo drives and motors. With representation in more than 75 countries, Beckhoff is well-positioned to provide global sales and service to its customers. Beckhoff sales and service are handled directly, with no intermediaries involved for exceptional customer service and consultation.