Bearings and Linear Guides Make Medical Equipment Safer and More Flexible

Technical equipment used in hospital operating theatres is subject to stringent requirements in terms of safety, reliability and flexibility. The contribution made by rolling bearings and linear guidance systems that are used in these instruments and mechanical devices is critical.

Operating tables and ceiling mounts, for example, have an important role to play in creating a flexible, reliable operating environment, which in turn, directly impacts the quality of the surgery being performed in the theatre.

Through its INA and FAG branded bearings and linear guides, the Schaeffler Group has developed a wide range of standard and custom bearing solutions that not only meet the rigorous quality and safety standards for operating theatres and other medical environments, but in some cases also exceed these standards.

Bearing solutions for ceiling mounts

In order to ensure the rapid, smooth changeover of medical staff and equipment for time-critical surgical procedures, designers of operating theatres now consider a flexible layout as the key priority. For safety reasons and to enable easy cleaning for infection control, supply lines are no longer installed along the floor of the theatre. However, at the same time, the amount of equipment used in surgical procedures is increasing.

Diagnostic imaging procedures performed during operations, for example, require extra space for monitors, which need to be positioned very close to the operating table. By attaching supply stations to ceiling mounts, it is possible to connect numerous devices, PCs and monitors without having to run cabling along the floor. Furthermore, the swivel arms on the mounts allow for flexible, customised positioning of equipment inside the operating theatre. Therefore, the ceiling mounts must be able to accommodate high loads, but move with minimal effort, while providing sufficient space for power, oxygen and data supply lines.

For these types of applications, Schaeffler Group developed its AXS axial angular contact roller bearing. Installed in pairs, this bearing withstands high loads and tilting moments, while ensuring that the movements of the ceiling mounts are smooth and quiet. The small cross-section of the bearing (its small radial section height relative to the large inner diameter) enlarges the cross-sectional opening of the swivel arm inside the ceiling mount, making it easier to feed multiple supply lines through.

AXS: lightweight, but handles heavy loads

The AXS angular contact bearing is compact and lightweight, which means installation space is optimised. The bearing rings are just 1.2mm thick with radial section heights of 7mm and 10mm. The bearings also offer very high load ratings, which allow a significant increase in bearing preload (e.g. in swivelling movements) that further enhances tilting rigidity, if required.

The AXS angular contact roller bearings' inner and outer rings are geometrically identical, therefore preventing any mistakes during final assembly. Together with the roller and cage assembly, the rings simply slide onto the shaft. In addition, ground bearing seats are no longer needed. The result is a bearing that is quick and easy to assemble, while the precision-turned seats, which are simple to manufacture, significantly reduce the overall cost of this component.

Schaeffler's ZAXFM bearing assembly, which can be either flange- or screw-mounted, is an advancement of the AXS series. Ready to mount, this bearing assembly is preloaded and greased from the factory. The adjusting nut is mounted directly to the bearing's inner ring and preloaded to the specified torque. This means the expertise of the fitter is no longer required, which minimises costs for the customer.

Linear motion systems for operating tables

An operating table has to be sturdy, whilst offering as much freedom of movement as possible. Vertical adjustment enables the table to adapt to the height of the surgeon, as well as transferring the patient to another bed or wheelchair.

This means the linear guides for these applications must meet stringent standards, including quality, reliability, load-carrying capacity and safety.

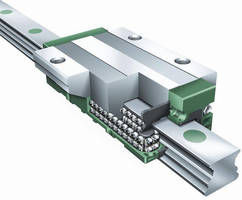

Schaeffler's KUVE and KUSE profiled rail linear guides are ideal. These linear recirculating ball bearing and guideway assemblies have four and six rows of rolling elements respectively, which offer extremely high load-carrying capacity.

As well as vertical adjustment, surgeons also need to be able to position the operating table along its horizontal axis. This is critical when performing intra-operative diagnostic procedures. When X-rays are taken using a C-arm, for example, intelligent positioning of the operating table can create the required space underneath the table to accommodate the lower half of the X-ray machine.

Schaeffler's KUVE linear guidance system is suitable for both linear and lateral adjustments, while its four rows of ball elements deliver high load-carrying capacity. A lubrication reservoir located near to the bearing raceway continuously supplies lubricant to the raceway elements. This ensures a long service life and minimal maintenance.

The linear guides are also available with Schaeffler's Corrotect® coating, which provides the rolling elements and raceways with optimal corrosion protection. Other coatings, such as TRIONDUR, ensure high wear resistance and outstanding dry-running characteristics in situations where there is insufficient lubrication.

For noise-sensitive applications, Schaeffler's INA four-row linear recirculating ball bearing and guideway assemblies use quad spacers located between the ball elements, which reduce the running noise significantly. Low friction levels also enable smooth running and precise positioning.

Non-magnetic bearing solution

Schaeffler also offers bearing solutions for stereotactic surgery, a surgical technique increasingly used in heart surgery. This technique provides ultra-precise control of catheters and other instruments. Using magnetic fields, a computer guides the tip of the catheter through the bloodstream and ventricles with the utmost precision, directly to the point of treatment. Since the viability and success of this procedure depends on magnetic fields, the operating table itself must be non-magnetic.

Therefore, any bearings or linear guides used must also be non-magnetic. Schaeffler's innovative, custom solution: the KUVE-B-AM linear guidance system has a permeability (µr) of less than 1.02.

For more information on Schaeffler's range of bearings and linear guides for medical equipment, please visit www.schaeffler.co.uk or contact the marketing department on info.uk@schaeffler.com and ask for a copy of the PMT brochure.

With a total of 66,000 employees at over 180 locations around the globe and group sales of 8.9 billion Euros (fiscal year 2008), the Schaeffler Group is one of the world's leading rolling bearing manufacturers and automotive component suppliers. The corporate group includes the INA Group with headquarters in Herzogenaurach, the FAG Group based in Schweinfurt as well as the LuK Group, with headquarters in Buhl.

Dean Palmer

Director

SilverBullet PR Ltd

The Grey House, 3 Broad Street,

Stamford, Lincolnshire PE9 1PG

Tel: 01780 753 000

Mobile: 07703 023 771

e-mail: dean@silverbulletpr.co.uk

www.silverbulletpr.co.uk

Schaeffler (UK) Ltd,

Forge Lane

Minworth

Sutton Coldfield

West Midlands B76 1AP

Tel: 0121 351 3833

Fax: 0121 351 7686

e-mail: info.uk@schaeffler.com

www.schaeffler.co.uk