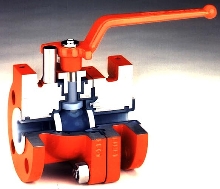

Ball Valves handle corrosive and high-purity media.

Share:

Press Release Summary:

Tufline full-port lined ball valves feature metal-to-metal body joint that controls compression of lining for heat and stress cracking resistance. Cast-in recesses and machined grooves lock lining to valve body and ball, making lining blow-out virtually impossible. Lining is unpigmented, chemically-inert virgin PFA. Both full-port and standard-port models conform to ANSI B16.10 dimensional specifications for short-pattern flanged-end ball valves.

Tufline full-port lined ball valves feature metal-to-metal body joint that controls compression of lining for heat and stress cracking resistance. Cast-in recesses and machined grooves lock lining to valve body and ball, making lining blow-out virtually impossible. Lining is unpigmented, chemically-inert virgin PFA. Both full-port and standard-port models conform to ANSI B16.10 dimensional specifications for short-pattern flanged-end ball valves.Original Press Release:

Metal-To-Metal Body Joint Controls Liner Compression In Tufline Full-Port Lined Ball Valves For Pulp, Chemical, Petroleum Processes

CINCINNATI, Ohio, Nov. 19 - The metal-to-metal body joint of the Xomox Tufline full-port lined ball valve family controls compression of the valves' lining for heat and stress cracking resistance. This allows them to economically handle corrosive and high-purity flow media. They often outperform far more expensive exotic alloy valves.

Cast-in recesses and machined grooves lock the lining to the Tufline valve body and ball, making lining blow-out virtually impossible.

The lining material chosen by Xomox for its Tufline lined ball valve is unpigmented, chemically-inert virgin PFA. Moisture absorption in the lining, locked in by the metal-to-metal body joint, is negligible.

Both full-port and standard-port Xomox Tufline models fully conform to ANSI B16.10 dimensional specifications for short-pattern flanged-end ball valves. Choices include standard stem packing or live-loaded, multiple-element stem packing. Seats are

easily replaced.