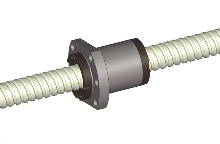

Ball Screw utilizes caged technology.

Press Release Summary:

Type SBK ball screw achieves maximum feeds of 120 m/min and permissible DN value of 160,000. Utilization of Caged Technology prevents ball-to-ball contact and associated friction, and allows balls to smoothly circulate in tangential line. Cage also acts as reservoir for lubricants, eliminating need for external lubricating system. Optional wiper ring acts as barrier to prevent foreign matter and swarf from entering nut interior.

Type SBK ball screw achieves maximum feeds of 120 m/min and permissible DN value of 160,000. Utilization of Caged Technology prevents ball-to-ball contact and associated friction, and allows balls to smoothly circulate in tangential line. Cage also acts as reservoir for lubricants, eliminating need for external lubricating system. Optional wiper ring acts as barrier to prevent foreign matter and swarf from entering nut interior.Original Press Release:

THK's New Ultra High-Speed Type SBK Ball Screw with Caged Technology & High Speed Design

Schaumburg, IL (August 26, 2002) - Featuring THK's Caged Technology, the new Type SBK ballscrew offers numerous benefits including ultra high-speed performance, low noise, no piping. It achieves impressive maximum feeds of 120m/min., and a permissible DN value of 160,000.

The utilization of Caged Technology means isolating each of the load carrying re-circulating elements in an individual cage or pocket. This cage prevents ball-to-ball contact and the associated friction. Furthermore, it allows balls to smoothly circulate in a tangential line. The cage also acts as a reservoir for lubricants, eliminating the need for an external

lubricating system. Specific benefits include increased speed and accuracy of motion, decreased noise levels, long-term, maintenance-free operation and reduced sources of contamination.

Long term, maintenance-free operation is enhanced with the optional QZ lubricator. Additionally, the optional wiper ring makes the Type SBK suitable for harsh environments. The wiper ring acts as a barrier to prevent foreign matter and swarf from entering the nut interior.

To learn more, visit THK IMTS booth #D-4254, visit their Web site at: www.thk.com, or contact THK America, Inc., 200 E. Commerce Dr., Schaumburg, IL 60173, Phone (800) 763-5459, (847) 310-1111, Fax (847) 310-1182, e-mail: chicago@thk.com.