Anisotropic Conductive Adhesives suit LCD manufacturing.

Press Release Summary:

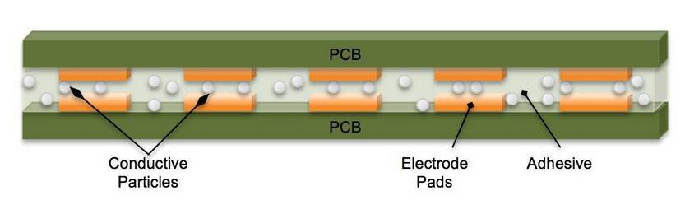

Available as paste, film, or pressure-sensitive tape, Anisotropic Conductive Adhesives are conductive in Z-axis and non-conductive in X- and Y-axis. During curing process, particles in adhesive become stacked in vertical configuration, providing conductivity for component that is mounted to surface, while remaining electrically insulating on X and Y axes. Applications include RFID manufacture, flat panel displays, and assembly of semiconductor modules.

Original Press Release:

Focus on Anisotropic Conductive Adhesives

Creative Materials, Inc., has developed a line of anisotropic conductive adhesives that are recommended for a wide range of applications, including LCD manufacturing, surface-mount connections in electronic devices, and RFID antenna assembly. Commonly known as Z-axis adhesives, these products are extremely useful in applications where high signal density is required in a smaller overall package. Ayer, MA - Creative Materials, Inc., introduces our line of Anisotropic Conductive Adhesives. Some of our best-selling products include 121-20, Anisotropically Conductive Low-Temperature Curing Epoxy Adhesive, 121-23, Anisotropically Conductive B-Stageable Epoxy Adhesive, and 121-24, Anisotropically Conductive B-Stageable Epoxy Adhesive Film. Our products are available in paste form, as films, and in a recently introduced line of anisotropically conductive pressure-sensitive tapes. How they work: Anisotropic or "Z-axis" adhesives are conductive in the Z-axis and are non-conductive in the X- and Y-axis. Visualize a three-dimensional space, where the X and Y axes represent the horizontal surface and the Z axis is the vertical interface with the surface. The Z axis can be though of as the direction of compression. During the curing process, the particles in an anisotropic conductive adhesive become stacked in a vertical configuration, providing enhanced conductivity for a component that is mounted to the surface, while remaining electrically insulating on the X and Y axes. This property provides increased conductivity within very tight physical areas, a requirement in consumer electronics manufacture, in such products as mobile phones, MP3 players, and CMOS cameras. Where they are used: Anisotropic conductive adhesives are used in RFID manufacture, for flat panel displays, and in the assembly of semiconductor modules. The applications are myriad, and new lower-temperature and faster curing methods have increased the breadth of applications. Among the advantages of these new developments are faster throughput and lower overall cost. Greater production efficiency can be achieved using these products since the anisotropic product itself provides alignment of the conductive particles, without the user having to create individual connections. These products provide superior conductivity, excellent adhesion to a variety of substrates, and are less sensitive to handling and extremes in ambient conditions. Please visit our website for a list of our anisotropic conductive adhesives: creativematerials.com/products/anisotropic-adhesives; to learn more about our new line of anisotropically conductive pressure-sensitive tape: www.creativematerials.com/news/pr-conductive-tapes-and-films.php. Creative Materials, Inc., is a leading manufacturer of electrically conductive inks, coatings, and adhesives. Products from Creative Materials are used in electronic components for computers, keyboards, cell phones, solar collectors, automobiles and aircraft, for medical electrodes, medical instruments, and heating equipment. Creative Materials is ISO 9001 certified, with an extensive product line that includes more than 1,000 products. The company is renowned for creating custom formulations that are used in a wide variety of global applications, providing cost-effective design solutions for demanding production requirements. With over 80 years of experience in the adhesives, ink and coating industry, our staff combines technical expertise with nimble production capabilities, enabling us to reduce time-to-market for new product applications. Our products are manufactured to order, with typical lead times of two or more weeks. Pricing is available upon request. For more information about this and other products, please visit our website at www.creativematerials.com, or contact us at info@creativematerials.com. We have moved! Please note our new contact information on our website, www.creativematerials.com/contact-us.