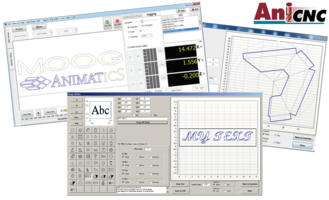

AniCNCâ„¢ Application Software features nested-array code building capability.

Press Release Summary:

AniCNC™ Application Software offers graphical human-machine nterface and G-code editing. Designed for Class 5 SmartMotor™, software is enabled with DXF file import, G-code export and dynamic jog and teach features for recording points to G-code program. AniCNC™ is included with TrueType font to G-code converter and built-in functions to tackle milling, routing, machining and shaping.

Original Press Release:

Moog Animatics Announces New ANICNCâ„¢ Application Software for Class 5 SMARTMOTORâ„¢

Mountain View, CA, USA – Moog Animatics, a division of Moog Inc., has announced the release of its new AniCNC™ application software exclusively for use with the Class 5 SmartMotor™. When coupled with the Class 5 SmartMotor, the AniCNC software solution provides a graphical Human-Machine Interface (HMI), G-code editing and runtime environment and other built-in features to tackle milling, routing, machining, shaping and related projects. An offline mode allows preview and refinement of G-code tool paths without being attached to the SmartMotor™.

Additional features include:

- A simple, intuitive user interface, optimized for touchscreen use

- Advanced Code Writer and Shape Writer for creating complex patterns

- DXF file import to produce scalable G-code for quick resizing and/or arraying

- G-code export to DXF format for efficient use in CAD or illustration software

- G-code editing and runtime environment with real-time viewing of the tool path

- TrueType font to G-code converter allows text scaling/framing

- Built-in functions for point-and-click programming of common metalwork shapes

- Nested-array code building for easy duplication of parts in sheet material

- Dynamic jog and teach to rapidly record points to the G-code program

- In-path jog correction allows temporary move adjustment and then resets and continues

The SmartMotor is a highly programmable servo motor system that is integrated with a motor, an encoder, an amplifier, a controller, RS-232/RS-485 and other optional communications and IOs. The motor provides a smaller footprint, a lower total cost and a simplicity to reduce machine development and build time.

Moog Animatics is a global leader in integrated motion control and designs, manufactures and markets motion control products and systems. With over 30 years of experience in the motion control industry, the company has U.S. operations and international offices in Germany and Japan and a network of Automation Solution Providers worldwide. Additional information about the company can be found at www.animatics.com.

Moog Inc. (NYSE: MOG.A and MOG.B) is a worldwide designer, manufacturer, and integrator of precision control components and systems. Moog’s high-performance systems control military and commercial aircraft, satellites and space vehicles, launch vehicles, missiles, automated industrial machinery, wind energy, marine and medical equipment. Additional information about the company can be found at www.moog.com.