Anchoring Spiraling Cable Costs - CNW933 Sinusoidal Wave Filter Overcomes Interference Problems

INDIANAPOLIS – The cost of cables is rising in manufacturing as the result of the need for lengthy shielded cable to tackle attenuation and electromagnetic compatibility (EMC) issues. Compounded by increasing commodity prices, this is leading many original equipment manufacturers (OEMs) to look for cost effective solutions. OEMs can anchor spiraling cable costs by using REO-USA sine wave filters.

The demand for cable lengths in industrial environments can be high. Variable speed devices (VSDs) and long cable runs over 165 feet between the VSD and the motor are common, but can conspire to create further electrical interference.

Three phase induction motor control has been greatly enhanced in recent years by the use of VSDs. The rotary speed of the induction motor can be easily manipulated by altering the frequency of the supply current. The result is a fixed voltage, variable frequency output. Although the benefit of the VSD is to lower cost by increasing efficiency, the process has some drawbacks.

Pulse with modulation (PWM), the process used to switch the VSD inverter typically between 8-16 kHz, produces a series of output pulses that average to a sine wave. The power conversion process creates unwanted frequency components such as harmonic currents which, in substantive quantities, can lead to electromagnetic interference (EMI).

The degradation caused by EMI can be significant and varied, wearing down the ability of components to operate at optimal performance and potentially even lead to machine failure. The damage ranges from overheating transformers, windings and capacitors, to interference affecting telecommunication equipment and metering apparatus.

As well as this, excessive currents in the neutral cable of a three phase system and high voltage fluctuations, known as electrical flicker, can affect the supply for domestic users on public low voltage networks or OEMs on industrial networks.

Continuous and problematic levels of EMI can constitute electromagnetic compatibility (EMC) issues, rendering some equipment unsafe to use. Standards set at European level dictate the minimum requirements for safe usage of VSDs in power drive systems (PDS). IEC/EN 61800-3 directives apply to manufacturers, panel builders and system integrators.

The purpose of these directives is to minimize harmonics and demand the assessment of all connected equipment prior to use and provide sufficient technical documentation for all users.

Further practical requirements aim to improve conduction and reduce radiation based emissions, as well as reduce the high voltage differences (dw/dt) generated from the high frequency switching of insulated-gate bipolar transistors (IGBT). Consequently, minimum requirements have been set for cabinet grounding and terminal quality using shielded cable.

To implement best practice, many manufacturers have gone one step further and sought to replace entirely or upgrade a significant portion of their cabling to shielded cable. It is no coincidence then that this higher demand for copper has raised the commodity pricing in international markets which, until recently, were falling.

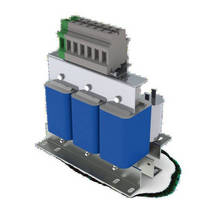

To provide an equally robust yet more cost effective solution, REO-USA has developed a special filter to overcome interference problems, which are inevitably exacerbated by the use of long cable runs. The 400V three line CNW933 sinusoidal filter range is available in units rated from 2-1200A.

The CNW933 eliminates the need for shielded cable by suppressing unwanted frequencies. This is achieved by an efficient use of various inductance and capacitance solutions - which eradicate harmonic currents - smoothing the peak waveform created by PWM and producing a near sine wave supply. Motor life is increased while noise, mechanical stress and thermal conduction are alleviated.

The cost savings of using standard cable can be considerable. In a typical drive installation using a 4kW drive at a distance of 650 feet from the motor, cable savings alone can be around $150. This means that almost three times as many installations could be cabled using standard cable as opposed to shielded.

These savings quickly mount up when larger drives are utilized. The savings for a typical 160kW installation is approximately $2,400. Considering REO-USA's sine wave filters can be used for cable lengths of up to 3280 feet, savings for this configuration would reach $12,000.

In a world becoming increasingly intangible, it seems that cabling is yet to be swayed. Despite the inordinate amount of regulatory complexity and financial pressure under which manufacturers operate, it is evident that there are still cost effective measures yielding longer term return on investment.

The advantages of CNW903 include:

• Low heat and noise

• In most instances the need for screened cables is avoided

• Easy installation

• Manufactured conforming to UL insulation system E251513 possible

• Adaptation to motor cables up to 3280 feet possible

• Also available with high ingress protection (CNW M 933 IP) or customer specific solutions

For more information, call (317) 899-1395, email info@reo-usa.com, or visit www.reo-usa.com.