AMETEK SCP Introduces Polyethylene Molding Capabilities with Embedded Sensors and Payloads

Press Release Summary:

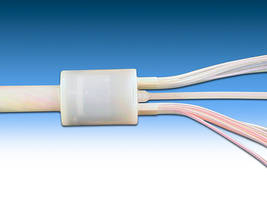

AMETEK’s new polyethylene molding capabilities provide long life and high reliability for full depth rated sea floor applications. Polyethylene is preferred for molding due to its lower permeability to seawater. These capabilities are provided at the factory or in-the-field to mold polyethylene cable splices, breakouts and connector terminations.

Original Press Release:

AMETEK SCP Announces Expanded Polyethylene Molding Capabilities

Westerly, RI -- AMETEK SCP, a provider of highly reliable, harsh environment interconnect solutions, announces new contracted polyethylene molding capabilities that it will use to pursue U.S. government multiple award, multi-year indefinite delivery/indefinite quantity (ID/IQ) contracts.

Polyethylene has long been recognized as a preferred material for undersea cables and terminators due to its lower permeability to seawater. AMETEK SCP provides its customers polyethylene molding because of its long life and high reliability for full depth rated sea floor applications with embedded sensors and payloads.

AMETEK SCP has worked with customers to mold polyethylene cable splices, breakouts and connector terminations. These capabilities can be provided at the factory or in-the-field. Customers are advised to consult with AMETEK SCP to best utilize its expertise in the proper selection of application of polyethylene materials to assure minimal life-cycle costs.

“We are very pleased to see that our investment in polyethylene resources are paying dividends. We have created a solid infrastructure of capital equipment, processes, and talent to support our customers,” comments Liam Shanahan, Engineered Interconnects and Packaging Business Unit Vice President.

About AMETEK SCP

AMETEK SCP is a unit of AMETEK Electronic Components and Packaging (ECP), a world leader in end-to-end electrical packaging and cable solutions for harsh environments, custom-engineered preforms and micro stampings. AMETEK ECP is a division of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices.

The polyethylene material is used for undersea cables and terminators due to its lower permeability to seawater. The polyethylene molding provides long life and high reliability for full depth rated sea floor applications. These capabilities enable the user to mold polyethylene cable splices, breakouts and connector terminations. It can be applicable at the factory or in-the-field.

For additional information, contact AMETEK SCP, 52 Airport Road, Westerly, RI 02891, USA. Telephone: +1 401-596-6658. E-mail: in+1-626-443-6610. Web site: www.ametek-ecp.com