AMETEK's Cost-effective Copper Core Connect an Alternative to Thick Solder Preforms Often Used in Electronic Packaging

Press Release Summary:

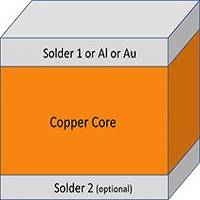

- Designed for use in place of thick solder preforms often made of expensive material

- Can be placed during a 2-D assembly process step using high melting point solder, allowing subsequent connections at higher elevations

- Configurations are available in Solder/Cu/Solder and Solder/Cu/Al(Au) for both soldering and wire or ribbon bonding

Original Press Release:

AMETEK Coining Launches Copper Core Connectâ„¢ for High-Performance Electronic Assemblies

Montvale, NJ -- AMETEK Coining, a leading manufacturer of solder and brazing preforms, is proud to launch the Copper-Core Connect™, an innovative, cost-effective alternative to thick solder preforms often used in high-performance electronic packaging.

The Copper-Core Connect is designed for use in place of thick solder preforms often made of expensive material. The product’s thermal and electrical conductivity can be up to seven times greater than alternatives, allowing for superior thermal management. Its innovative design grants end-users the ability to create final, high-powered, wire/ribbon connections to contact spots that otherwise cannot be reached or must be made earlier in the assembly process.

Additionally, the Copper-Core Connect alleviates common issues surrounding mismatched top and bottom solders often found in highly-engineered materials. It can be configured so that it is soldered to the ground-level board and work with or without a matching top-side board. For example, the Copper-Core Connect can be placed during a 2-D assembly process step using high melting point solder, allowing subsequent connections at higher elevations.

The Copper-Core Connect is customizable to fit the requirements and processes of end users in a variety of industries, including optical networking, microwave communication, defense, automotive and medical device manufacturing. The configurations are available in Solder/Cu/Solder and Solder/Cu/Al(Au) for both soldering and wire or ribbon bonding.

“Our engineering innovation teams heard from many customers that the design limitations of existing technology created problems for some high-performance designs,” Maurice Mevissen, Vice President & Business Unit Manager, AMETEK Coining. “This technology gives the package design engineer flexibility to realize much more challenging design targets.”

About AMETEK Coining

AMETEK Coining is a unit of AMETEK’s Electronic Components and Packaging (ECP) division, a world leader in end-to-end electrical packaging and cable solutions for harsh environments, custom-engineered preforms and micro stampings. AMETEK ECP is a division of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices.

For additional information, contact AMETEK Coining, 15 Mercedes Drive, Montvale, NJ 07645, USA. Telephone: +1 201-791-4020. E-mail: coining.sales@ametek.com Website: www.ametek-ecp.com

Contact:

Zhiguo Zhang, Zhiguo.Zhang@ametek.com