Alumina Ceramic withstands temperatures to 3,000°F.

Press Release Summary:

High-density, full-fired Aremcolox(TM) 502-1400 96% pure alumina ceramic exhibits abrasion, corrosion, electrical, chemical, and erosion resistance. Compressive strength is 340,000 psi, flexural strength is 46,000 psi, and dielectric strength is 225 V/mil. Aremcolox(TM) 502-1400 parts are fabricated to close tolerances through injection molding, isostatic pressing, and diamond machining processes. Lapped, polished, and metallized surface finishes are also available.

Original Press Release:

New Aremcolox 502-1400 96% Alumina Now Available

Valley Cottage, NY - January 26, 2007

SUMMARY

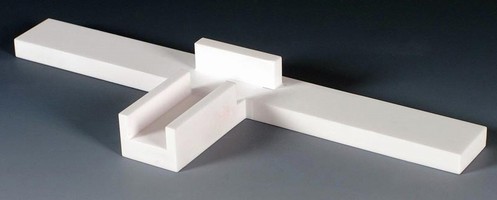

Aremcolox(TM) 502-1400, a high density, full-fired, alumina ceramic produced by Aremco Products, Inc., is now used to fabricate high temperature fixtures used in applications to 3000ºF (1650°C).

FEATURES

Aremcolox(TM) 502-1400 is a high density, full-fired, 96% pure alumina ceramic that provides exceptional abrasion and corrosion resistance as well as high mechanical strength and electrical resistance for continuous operating temperatures to 3000°F (1650°C). Properties include a compressive strength of 340,000 psi, flexural strength of 46,000 psi and dielectric strength of 225 volts/mil.

Aremcolox(TM) 502-1400 demonstrates exceptional chemical and erosion resistance. It experiences no weight loss when exposed to high concentrations of sulphuric acid for extended periods of time and demonstrates a very low index of volume loss upon extensive impingement and erosion tests.

Aremcolox(TM) 502-1400 parts are fabricated to close tolerances thru injection molding, isostatic pressing and diamond machining processes. Lapped, polished and metallized surface finishes are also available. Typical applications include burner nozzles, alignment fixtures, bobbins, combustion chambers, feed-thrus, pump liners, rail guides, stand-offs, and wear tiles.

For more information about this advanced product, please contact Aremco's Technical Sales Department. Please fax or email engineering drawings to receive a quotation.