Material Processing Barrels and Drums

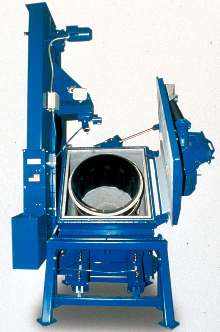

Abrasive Blast Cleaner processes small parts.

Press Release Summary:

Wheelabrator® Barrel Blaster consist of 13½ in. diameter, 12 bladed wheel unit, powered by 15 hp, 3,600 rpm, NEMA T-frame, direct mounted motor. Barrel is 32 in. diameter and 37 in. deep, providing 3 ft³ tumbling capacity for up to 600 lb. Adjustable, pneumatically-operated butterfly valve allows for positive media flow control. System provides contaminant removal, peening, and surface finishing of small parts.

Original Press Release:

The Wheelabrator Barrel Blaster Enables Processing of Small Parts in Small Spaces

LaGrange, GA - (September 15, 2003) -The Wheelabrator® Barrel Blaster enables the processing of a wide variety of small parts that conventional machines cannot handle. With an easy to install, space saving design, the Barrel Blaster is ideal for contaminant removal, peening, surface finishing, and small nonferrous foundries (non-sand).

Because the Wheelabrator Barrel Blaster reduces pinch point problems, it allows smaller parts to tumble uniformly in the abrasive blast for optimum cleaning and surface preparation. It is well suited for parts that are too small for conventional endless rubber belt and metal flighted Tumblast(TM) style machines.

The Wheelabrator Barrel Blaster consists of a 13 ½" diameter, 12 bladed wheel unit, powered by a 15 h.p., 3600 rpm, NEMA T-frame, direct mounted motor. The 32" diameter barrel is 37" deep, providing a 3 cubic feet tumbling capacity for up to 600 pounds. An adjustable pneumatically operated butterfly valve allows for positive media flow control. Options for the Wheelabrator Barrel Blaster include: Automatic abrasive adder, Variable speed wheel motor, lime adder assembly, dust collector (CFM required 2000) and cyclone separator.

The machine's compact design saves valuable floor space and permits easy installation. An overall height of 12'-0" accommodates one piece shipping, so the Barral Blaster is delivered ready to set in place. Requiring only a 7'-2" x 11'-9" footprint, it is pre-wired for immediate connection to the user's power supply and ventilation system.

From its safety blue color to the pneumatic locking clamp that secures the wheel door during a blasting cycle, the Barrel Blaster offers many protective systems, enhanced efficiency and effectiveness. Individual fuse blocks, starters and overloads for each motor prevent electrical problems. Features such as timed operation and a limit switch keep the machine from operating when the wheel door is open.

Founded in 1907, Wheelabrator is one of the most recognized names in the blast cleaning and surface preparation industries. Wheelabrator designs and builds a full line of blast cleaning equipment and systems suitable for a variety of finishing requirements at their LaGrange, Georgia facility. For more information on Wheelabrator visit www.surfacepreparation.com or send an e-mail to info@surfacepreparation.com.