Rubber / Foam Cutters and Cutting Machinery

Conveyor Belt Cutting Tool utilizes chain-drive crank.

Press Release Summary:

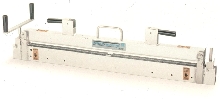

Clipper® 845LD Cutter, for light-duty conveyor applications, offers extra-strength belt-clamping springs, 90 deg squaring attachment, and external take-up control. Crank-driven 845LD assures single-pass cutting with virtually no resistance through rubber and PVC belting up to 1/2 in. thick. Offered in 36, 48, 60, and 72 in. lengths, cutter includes top-mounted double-handle crank, dual-edged blade, and crank sockets at each end.

Clipper® 845LD Cutter, for light-duty conveyor applications, offers extra-strength belt-clamping springs, 90 deg squaring attachment, and external take-up control. Crank-driven 845LD assures single-pass cutting with virtually no resistance through rubber and PVC belting up to 1/2 in. thick. Offered in 36, 48, 60, and 72 in. lengths, cutter includes top-mounted double-handle crank, dual-edged blade, and crank sockets at each end.Original Press Release:

New Clipper(R) 845LD Aluminum Conveyor-Belt Cutter From Flexo Offers Lighter Weight, Easier Use For Light-Duty Applications

DOWNERS GROVE (IL), JAN. 21, 2002 -- A new aluminum conveyor-belt cutting tool from Flexco, designated the Clipper® 845LD Cutter, augments the company's earlier steel cutter line with 15% lighter-weight alternatives for easier handling, plus added features for better operation.

Designed for light-duty conveyor applications such as food processing, agricultural and in-plant parts/package handling, the 845LD adds extra-strength belt-clamping springs that prevent shifting during the cut. This assures the straight, smooth, perpendicular cut essential for proper installation of mechanical belt splicing, longer splice life and a truer-tracking belt. In addition, a 90 degree squaring attachment is offered as a time-saving option for use with new belts, an external take-up control allows convenient field adjustment of blade drive-chain tension, and aluminum construction keeps the tool free of corrosion.

Unlike conventional push/pull belt cutting tools, the crank-driven 845LD assures single-pass cutting with virtually no resistance, through rubber and PVC belting up to 1/2" (13mm)thick. The new cutter is offered in four lengths: 36", 48", 60" and 72" (900, 1200, 1500 & 1800mm).

Cutter operation is simple and designed for greatest possible safety, even in tight workspaces: after proper belt-squaring procedures, the user lifts the tool's clamp bar, positions the belt across the cutter-blade track, lowers the clamp bar and secures it with a detent pin. Two top-mounted spring clamps are activated to hold the belt firmly in place. The user then turns a top-mounted double-handle crank to draw the tool's dual-edge blade through the belt in either direction; the unit's chain-drive crank system significantly reduces the effort and time required to make a cut.

A crank socket at each end of the cutter body accommodates situations in which workspace is available only along one side of the tool. The hold-down bar can be secured in an open position to eliminate the need to manually hold it while aligning the belt over the cutter-blade track. For low-clearance situations, the hold-down bar can be completely detached. For greater safety, the top of the blade is flat and blunt, and steel pockets at both ends of the blade track provide guarded areas for parking the cutter blade while the tool is open.

Each unit arrives with one blade installed; replacement blades, sold separately, are easily installed by the user. Flexco belt cutters can be bench-mounted for workshop applications or carried with a convenient, built-in handle for remote on-line belt repairs.