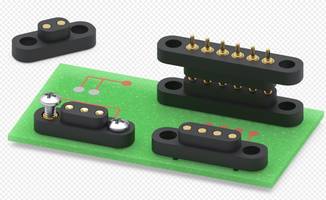

4mm Pitch Target Connector comes with flanged base.

Press Release Summary:

4mm Pitch Target Connector is compatible with 858 series ruggedized spring loaded connector. Available in 2-6 positions in through-hole, SMT and SMT with alignment pin versions, Product comes in high temperature molded Nylon 46 housing and comes with flat or concave face on the mating side of the pins. Connector comes with tab holes, mounting tabs and pin length tolerance of ±.001 in. and provides co-planarity of .005 in. Unit’s pins are plated with 10 micro in. gold over nickel.

Original Press Release:

Mill-Max Announces New 4mm Pitch Target Connector

Mating target connectors for rugged spring loaded connectors

Mill-Max Manufacturing Corp., Inc. today announces a new target connector on 4 mm pitch designed for rugged applications incorporating a flanged base and hardware options for secure mounting. This target connector series is the mating half to the recently released 858 series ruggedized spring loaded connector.

Offered in 2-6 positions in through-hole, SMT and SMT with alignment pin versions, this new target connector series features a high temperature molded Nylon 46 housing that is compatible with RoHS soldering processes. Mounting tabs, integrated into the housing, provide a means for secure attachment to the PCB or product assembly. The tab holes may be specified with threaded inserts or left empty for other hardware requirements. The flanged base provides stability for the connector. The pins are plated with 10 micro inches hard gold over nickel for durability and excellent conductivity.

Additionally, these connectors are offered with the choice of either a flat or concave face on the mating side of the pins. The flat face style is .082” (2,08 mm) in diameter providing ample target area for the .050” (1,27mm) diameter mating plunger. Concave face targets provide additional surface area when mated and can aid in centering/alignment of components fitted with spring loaded connectors during manual engagement.

In common with all Mill-Max products the new target pins employ high-speed precision turning with tight tolerances. The overall pin length tolerance of ±.001” (,0254 mm), combined with established in-house manufacturing and assembly techniques produce a connector with co-planarity of .005” (0,127 mm) or better. Advanced machining processes are employed to ensure there are no cut-off burrs on the face or SMT base of the pins to impede the electrical connection and attachment to the P.C.B. The table below provides details of the features for each part number in the series.

Part # Termination Style Threaded Insert Alignment Pins Face Style

858-10-00X-10-001000 Through Hole No No Flat

858-10-00X-10-011000 Through Hole Yes No Flat

858-10-00X-10-002000 Through Hole No No Concave

858-10-00X-10-012000 Through Hole Yes No Concave

858-10-00X-30-001000 SMT No No Flat

858-10-00X-30-011000 SMT Yes No Flat

858-10-00X-30-601000 SMT No Yes Flat

858-10-00X-30-611000 SMT Yes Yes Flat

858-10-00X-30-002000 SMT No No Concave

858-10-00X-30-012000 SMT Yes No Concave

858-10-00X-30-602000 SMT No Yes Concave

858-10-00X-30-612000 SMT Yes Yes Concave

Contact the technical support team at Mil-Max Mfg. to discuss your particular requirements and applications.

Please visit the www.mill-max.com/PR680 for samples and more detailed information on this and other Mill-Max products.

About Mill-Max

Mill-Max is the leading US manufacturer of machined interconnect components with a vertically integrated manufacturing facility headquartered at 190 Pine Hollow Rd., Oyster Bay, NY 11771. Its full product line includes spring-loaded connectors, SIP, DIP, PGA and BGA sockets, board-to-board interconnects and pin headers, surface mount and custom products, PCB pins and receptacles, solder terminals, wrapost receptacles and terminals. The company’s complete manufacturing facility includes engineering, tooling, primary and secondary machining, stamping, plating, injection molding, and assembly.

For more information, contact Mill-Max Mfg. Corp. Applications Engineering, techsupport@mill-max.com; www.mill-max.com.

Contact:

Claude A. Bahnik

Chief Executive Officer

Mill-Max Mfg. Corp

P: 516-922-6000 ext 230

F: 516-470-9132