VORTAB Flow Conditioners Improve Liquid Flow Meter Accuracy and Repeatability

Share:

Improved Accuracy for dP, Magnetic, Ultrasonic and Turbine Flow Meters

San Marcos, CA — Process and plant engineers who need to add a liquid flow meter in already crowded equipment areas where there is an insufficient straight pipe run will find VORTAB® Flow Conditioners ensure a smooth flow profile for accurate measurement by flow meters, which often must be installed in close proximity to pumps, valves or elbows due to limited plant real estate.

A number of popular liquid flow meter meters, including differential pressure (dP), magnetic, ultrasonic and turbines, feature sensing technologies that can be significantly affected by asymmetrical flow conditions in the pipe. These conditions degrade measurement accuracy and repeatability. Depending on the particular technology, these meter sensing technologies require a minimum of 6 to 10 upstream and up to 5 downstream straight pipe diameters to a achieve a symmetrical swirl-free flow profile for accurate measurement.Â

Unfortunately, most process industry plants are rich with bulky equipment and other real estate limitations, which make it difficult to achieve the required pipe straight-run configuration necessary for accurate liquid flow measurement. Many times too, plant upgrades and retrofits require adding more flow meters in locations that are difficult to accommodate without flow conditioning devices because of their straight pipe run requirements. VORTAB Flow Conditioners reduce the required straight pipe diameters to only a very few diameters for effective compact meter installation and accurate flow measurement.

Furthermore, the design of the VORTAB Flow Conditioners results in an extremely low pressure drop. This design feature provides significant energy cost savings over alternative flow conditioning technologies and maximizes attainable plant product throughput. Non-recoverable pressure loss can reduce maximum flow capability in process lines, creating process inefficiencies and requiring greater energy expenditures to move process liquids and gases.

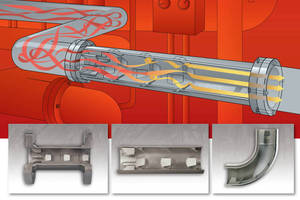

There are four different VORTAB Flow Conditioner models to accommodate a variety of process requirements. The VORTAB Insertion Sleeve (VIS) is the most cost effective version of the VORTAB flow conditioning products. The VIS can be installed directly into existing pipe or specially designed to meet unique piping configurations.

The VORTAB Meter Run (VMR) Flow Conditioner offers a complete, simple pipe section replacement for new and existing piping systems. The VMR is a seven pipe diameter long spool piece comprised of three pipe diameters of VORTAB flow conditioning internals and a built in downstream settling chamber.

The VORTAB Short Run (VSR) flow conditioner offers a simple flow conditioning pipe section replacement for new and existing piping systems. The VSR is a three pipe diameter long flow conditioning spool piece with just the VORTAB flow conditioning internals.

The VORTAB Elbow™ Flow Conditioner is a 90° long radius elbow (VEL) model. It offers a simple flow conditioning elbow replacement for new and existing piping systems. The VEL is the only true isolating elbow flow conditioner in the world. It not only has the ability to isolate irregular velocity profiles and swirl normally encountered in a single elbow, but it also has the ability to isolate any irregular velocity profiles entering the VEL.

The Vortab Company is a global supplier committed to meeting the needs of its customers through innovative solutions to the most challenging requirements for optimizing flow meter accuracy and repeatability in gases or liquids.

Product Information Contact: Vortab Company: 1755 La Costa Meadows Dr, San Marcos, CA 92078

Web: www.Vortab.com E-mail: eflow@fluidcomponents.com Tel: 800-854-9959 Tel: 760-736-6114 Fax: 760-736-6250

Â