The Best of Both Worlds - Increasing Motor Life and Reducing EMI while Increasing ROI

Business purchasing decisions are increasingly being made in a vicious cycle of short-termism, even under circumstances where a long term strategy may yield higher return on investment (ROI). At a time when austerity measures are leading businesses to cut costs, manufacturers can use high current line reactors to make considerable energy savings, increase motor life and reduce electromagnetic interference (EMI) issues.

There is no doubt that we are living in an era of unprecedented change and a world where competitiveness has captured the hearts and minds of decision makers. From lean and kaizen in manufacturing to third tier auditing in supply chains, the push towards reducing carbon emissions using green technology saving money is high on the agenda. The way has been paved rapid business growth and the rise of empires in the space of a few decades.

However, in some cases this change has come at the cost of a long term perspective. Traditionally the most successful businesses have been those whose strategy has struck a good balance between short term efficiency and long term return on investment.

Short term parochialism has often led companies into a vicious downward spiral. Many reputations have been left in tatters in the pursuit of price and chasing cheap, almost always by sacrificing long term quality and service.

Increased pressure to conform to legislative and corporate social responsibilities has further intensified the burden on companies to deliver high quality, on time and under budget. For instance, the eco design directive covering electric motors – EC 640/2009 – mandates that from January 1, 2015, all new motors must be equipped with a variable speed drive (VSD) by default.

In industrial applications a VSD is often used to control the speed of a motor. This increases efficiency and provides cost savings. However, the process is not completely without drawbacks. In order to control the motor speed, the supply current is manipulated using pulse width modulation (PWM) for high frequency switching.

The resultant fixed voltage, variable frequency supply outlet, while able to control motor speed, creates unwanted EMI and harmonic currents, whose high frequencies can damage equipment. Overheating of transformers, windings and capacitors as well as interference on telecommunications equipment and metering apparatus can render equipment unusable.

European legislation has sought to solve the problem through the introduction of the IEC/EN 61800-3 directive, which makes it obligatory for manufacturers, panel builders and system integrators to ensure that all equipment is electromagnetically compatible with surrounding devices.

It is the combination of these factors which ultimately impacts the triple bottom line: price, people and planet. Procurement and finance managers must make decisions which not only impact profitability but also the people and environment around them. Although ever decreasing budgets require intense scrutiny of any expense, some simple changes can result in significant savings.

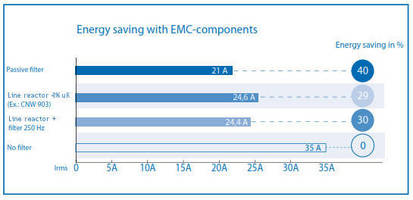

Price is the first "P" of the triple bottom line. To provide OEMs with a simple way to reduce energy costs, REO has developed an EMC compliant line reactor. The CNW903 three-phase high current line reactor removes harmonic currents and EMI from the power supply, reducing any voltage distortion which could degrade or damage equipment.

The unit's small and efficient design has been achieved through careful selection of build materials and the application of design experience, which has resulted in a unit that requires much less panel space and incorporates shielded terminals and protection covers.

In a typical example, a CNW903 reactor costing only a little more than $75, on a 4kW VSD achieved such significant energy savings that ROI was realized in less than five weeks. This amounted to nearly $1,000 savings in the first year alone, an incredible savings considering the unit also increases motor life by reducing harmful harmonic current and EMI.

People are the second "P". As anyone that works in an industrial environment will know, working conditions on the factory floor can be demanding. Ear noise and hand protection is the norm. The CNW903 is able to eliminate excess heat, acoustic noise and component vibration - including mechanical stress on machinery - by reducing the overheating of in-phase neutral conductors. This means a quieter and cooler working environment for everyone.

Planet is the final "P". By reducing energy bills, companies can expect to meet and exceed not only government targets for carbon emissions, but also corporate social responsibility goals. Green credentials and brand awareness is also enhanced.

So why is it that, even though equipment such as the CNW903 exists, many companies are yet to realize these cost savings and improve their ROI?

The advantages of CNW903 are many, including:

• UL-listed

• Compact construction

• Low temperature rise

• Connection via terminals (wire is an option)

• Low noise

• Manufacture concerning to UL insulation E251513

• Available with high ingress protection (CNW M 903 IP), liquid cooled (CNW MC 903) or customer specific solutions.

CNW903 has a standing mounting profile and conforms to EN 60289 / EN 61558 with a test voltage of L-L 2500 V, DC 1s; L-PE 2500 V, DC 1s, and rated voltage of V=3x500V. Insulation material class is T40/F; Protection is IP00 and Climartic category is DIN IEC 60068-1, with Overload of 1.5xINenn 1 min/h.

With protection IP00 up to IP65, all reactors are available with high protection classes and encapsulated. The special design allows external mounting outside of the inverter and without the need for an additional enclosure. They are particularly robust and protected from dust, liquids and slurries.Â

For more information, call (317) 899-1395.