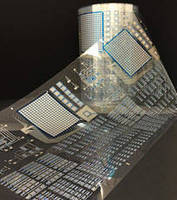

Printed Circuits from Topflight® are a Time- and Cost-Saving Alternative to Traditional Production Methods

Recent advancements in ink have not only resulted in higher conductivity, but it is also more abrasion resistant, flexible, stretchable and washable. Inks can be applied to polyurethane films, wovens, non-wovens and various other thin, flexible substates.

Our team of R D engineers will explore a variety of materials, inks and processes to develop the best solution for your application, which could include wearable technology, flexible electronics, RFID, sensors, or even energy storage.

• Polymer Thick Films (PTF): fine line traces to 6 mils - silver, carbon and silver/silver chloride are custom blended to attain specific resistivity values

• Etching: copper and aluminum etching can be done on a variety of substrates (PET, PEN, Kapton) resulting in higher conductivity

• Nano-particle Inks: high performance at up to 50% lower cost than conductive inks with similar resistivity. Graphene (carbon- nanoparticle) inks are also available with a lower cost and comparable resistivity to PTFs.

Lower costs and finer lines (as low as 3 mils) mean that components can be smaller than ever. To get a quote or a printed sample, contact us below.

About Topflight® Corporation

Topflight Corporation is a leading manufacturer of pressure sensitive labels, shrink sleeves, die-cut components, conductive printing and brand security solutions for companies in the medical, health and beauty, electronics, and durable and consumer goods industries. Topflight has locations in the U.S., South America, Europe and Australia.

Contact:

Regina Todd

Marketing Manager

rtodd@topflight.com

www.topflight.com