OMAX® Showcases Advanced Waterjet Cutting CAM Software at FABTECH 2014

Intelli-CAM™ seamlessly generates tool paths from 3D models and simplifies complex part processing

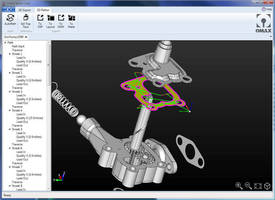

KENT, Wash. — OMAX Corporation showcased a highly advanced computer-aided manufacturing (CAM) software tool that further simplifies the cutting of complex, precision parts on its JetMachining® Centers at FABTECH 2014 in booth B3361. Free to OMAX owners, the new Intelli-CAM 3 software, which interfaces directly with the company’s intuitive Intelli-MAX® Software Suite, easily generates 3D tool paths from solid 3D models as well as quickly performs 3D to 2D file conversions.

Intelli-CAM, through its 3D Pather tool, quickly generates multi-axis, machine-ready tool paths from complex 3D solid models. In fact, Intelli-CAM automatically recognizes viable cutting surfaces from those 3D shapes, including variable bevels and tilted cones. This special functionality eliminates the need to manually add 3D attributes to a 2D file, thus allowing users to significantly reduce their production times.

With its user-friendly and powerful 3D to 2D conversion system, Intelli-CAM generates machine-ready cutting geometry through a few simple computer mouse clicks. With the 3D file imported, users extract the desired 2D profile directly from a slicing plane, shadow or face. Intuitive navigation tools make it easy for users to position and orient the slice – including rotations around all axes, orienting to a face, or projecting as a shadow.

Offered as a free update for existing JetMachining Center owners, Intelli-CAM operates as a standalone application or in tandem with several of the popular third-party 3D CAD systems. It supports a wide range of neutral and native 3D file formats – CATIA, SolidWorks®, Solid Edge, Autodesk® Inventor®, Siemens® NX, Pro/E®, Creo®, Step, IGES, VDA-FS, ACIS, Parasolid®, 3D DXF and DWG – so that OMAX customers avoid having to purchase expensive CAD software filter packages. Intelli-CAM also supports direct interface with CAD software such as SolidWorks, Inventor and Rhinoceros®, which allows users to launch Intelli-CAM directly from those applications.

According to Carl Olsen, lead software engineer for OMAX Corporation, Intelli-CAM allows the Intelli-MAX Software Suite to support just about any 3D or 2D CAD file or artistic drawing. “Our job shop customers will greatly benefit from Intelli-CAM as they will rarely ever again have to ask their customers to re-save a file to a format they can accept – because they can now accept nearly all of them,” he said.

He also noted that customers doing 3D programming for 5-axis waterjet cutting will find Intelli-CAM 3 greatly simplifies those operations as well, suggesting that Intelli-CAM “may be the easiest to use 5-axis CAM software ever, and it’s free.”

About OMAX Corporation

OMAX® Corporation designs and manufactures the world’s most advanced abrasive waterjet technology in a variety of table sizes and price points at its headquarters in Kent, Washington. Backed by unmatched support and powered by the company’s intuitive control software, OMAX and MAXIEM® JetMachining® Centers bring affordable performance to a continuously expanding range of industries. For more information on OMAX products and accessories, contact Sandra McLain at (800) 838-0343or visit www.omax.com.

Sarah Knight

Public Relations Manager

dgs Marketing Engineers

317.813.2224 Direct

317.813.2222 Main

Web: www.dgsmarketing.com