New Transver SDI Distribution System Offers High Flexibility and a Balanced Product Flow

Designed for high row rates and gentle handling

Patent pending movable waiting belt

Fast, flexible, and balanced product distribution process

Fits perfectly with other packaging solutions from Bosch

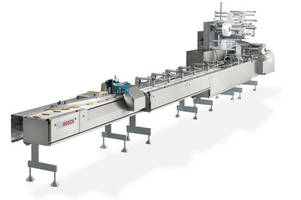

Las Vegas, Nevada – Customers from Bosch Packaging Technology benefit from its complete solutions to efficiently link process equipment and packaging. An example will be shown at PACK EXPO Las Vegas 2015 with the innovative Transver SDI product distribution system which will be exhibited as part of a Module++ system including an infeed system and a horizontal flow wrapper for bar packaging. The Transver SDI distributes products to the Pack Feeder 4 infeed system. The sophisticated integrated product inspection on the feeding system detects and rejects misaligned products. As a result, machine stops are minimized, and productivity is increased. Finally, the bars are packaged on the Pack 401 horizontal flow wrapper, ensuring with tight seals. In addition, all Bosch primary packaging solutions can be complemented with processing machinery and secondary packaging equipment to provide end-to-end system solutions.

The Transver SDI has been developed by Rotzinger AG, the leading supplier of product flow control, distribution and storage technology, and its affiliate Transver AG. Bosch Packaging Technology, a leading company in the field of processing, packaging and handling systems, is a minority shareholder of Rotzinger. This collaboration provides Rotzinger with a strong partner, distinguished by a global footprint and sales network.

Transver SDI – flexible, fast and easy to integrate

Thanks to its indirect feeding configuration the Transver SDI (Smart Distribution Downwards Indirect) is capable of handling high row rates. The movable waiting belt allows for a wide range of applications, including bars, biscuits as well as highly delicate, fragile or sticky products. It can be easily integrated with Bosch's broad portfolio of packaging solutions, such as the low-pressure Pack Feeder 4 infeed system and Pack 401 horizontal flow wrapper to help food and confectionery manufacturers increase efficiency.

"From the very beginning, our engineers focused on creating a system that could be easily connected with Bosch's packaging machines and any other third party packaging equipment. Customers can now benefit from the complete line solution as well as the single point of contact through the entire project. With innovative features for handling delicate products at high production speeds, low maintenance and fast changeovers, the Transver SDI will help customers achieve high Overall Equipment Effectiveness (OEE)," said Markus Kaufmann, chief executive officer of Rotzinger AG.

Gentle and fast product handling thanks to innovative movable waiting belt

The distribution belt tilts downwards to separate a single row of products from the product flow onto the waiting belt. This product row is then transferred onto the cross feeding belt immediately after the preceding row has left, independent of the incoming product flow (indirect feeding configuration). To discharge the row, different options can be selected. Option one: the waiting belt gently deposits the products with horizontal movements onto the cross feeding belt. This perfectly suits the handling of sticky, delicate or fragile products. Option two: the waiting belt feeds the products onto the cross feeding belt at high speed without horizontal movements. This method is applicable for robust and stable products. Thanks to the servo-drive technology of the Transver SDI station, the two options can also be combined: depending on the product, product rows can be partly deposited with a shorter horizontal movement resulting in a faster feeding onto the cross feeding belt.

Specifically designed to prevent product damage during the transport and distribution process, the system's tilting depositing function does not require any pushers or stoppers: the Transver SDI features a smart concept where rows are aligned by a short horizontal movement with the tip of the movable waiting belt.

High productivity thanks to higher row rates

The indirect feeding configuration enables high distribution speeds and adds flexibility to the production. Thanks to the movable waiting belt, the system is able to handle double rows or even batches and helps to ramp up the distribution process more quickly As a result, production speeds of up to 120 rows per minute and distribution speeds up to 40 rows per minute can be achieved. The distribution of the products is well balanced and therefore prevents oscillation of the downstream packaging process. To ensure high efficiency and reliability, the Transver SDI features the latest servo-drive technology.

Fast changeover and cleaning

The Transver SDI product distribution station is designed for fully automated format changes and simple adjustment to product-specific characteristics. This results in a very short changeover time. Gap closing belts ensure a continuous product flow to the packaging machines. The design ensures gentle product handling and minimized cleaning effort while also keeping maintenance requirements low as no pushers, stoppers, and side guides are needed. Its stainless steel construction and modular design allow for easy cleaning and maintenance. The waiting belt and cross feeding belt are mounted on a removable trolley that allow for high accessibility.

Flexible line configurations

The Transver SDI also offers flexibility in the line configuration, allowing manufacturers to adapt the system to a wide range of applications. For example, product overflow can be refed into the last station either at the end of the production (indirect refeed) or during production (direct refeed).

Enhancing flexibility with easily integrated options

Bosch will also exhibit its Pack Series of horizontal flow wrappers, which range from entry-level models to fully automated solutions. Designed for full automation, the Pack 401 provides a range of options including advanced feeding, automatic film splicing, as well as product inspection and rejection technology. The high-speed wrapper is available as stand-alone equipment, or can be easily combined with other packaging machines such as product handling equipment and various infeed systems like the Transver SDI, Delta robots and secondary packaging for complete solutions. The Pack 201 for mid-range automation is an easy-to-maintain machine designed to handle delicate products such as bakery goods, candy bars, wafers, biscuits and non-food products – also in trays. Adjustable folding boxes enable fast format changes for various product sizes, enabling maximum machine efficiency and improved package quality. The Pack 101 is an entry-level solution that offers the widest product size range currently available for wrappers in its class, with quick and easy setup and changeovers for increased operational efficiency. Flexibility is enhanced with the fully adjustable former and multiple cutting head sizes, which permit a wide range of products to be packaged on a single machine, reducing the need for future investments and giving manufacturers the agility to quickly adapt to changing market demands.

The Transver SDI and Pack Series will be displayed at PACK EXPO Las Vegas, Nevada from September 28 to 30 at booth C-2800. To learn more about these technologies, visit www.boschpackaging.com

Press photo: 1-PA-21488, 1-PA-21489, 1-PA-21490, 1-PA-21491

Contact:Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â

Alana Brown                               Â

phone: +1 715 243-2296Â Â Â Â Â Â Â Â Â Â Â Â

Contact person for press inquiries:

Christin Poenisch

phone: +49 711 811-58502

Based in Waiblingen near Stuttgart, Germany, and employing 6,100 associates, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology. At over 30 locations in more than 15 countries worldwide, a highly-qualified workforce develops and produces complete solutions for the pharmaceuticals, food, and confectionery industries. These solutions are complemented by a comprehensive after-sales service portfolio. A global service and sales network provides customers with local points of contact. Additional information is available online at www.boschpackaging.com

Having established a regional presence in 1906 in North America, the Bosch Group employs some 28,700 associates in more than 100 locations, as of April 1, 2015. In 2014, Bosch generated consolidated sales of $11.3 billion in the U.S., Canada, and Mexico. For more information, visit www.boschusa.com, www.bosch.com.mx and www.bosch.ca.

The Bosch Group is a leading global supplier of technology and services. It employs roughly 360,000 associates worldwide (as per April 1, 2015). The company generated sales of 49 billion euros in 2014.* Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. The Bosch Group comprises Robert Bosch GmbH and its roughly 440 subsidiary and regional companies in some 60 countries. Including its sales and service partners, Bosch is represented in roughly 150 countries. This worldwide development, manufacturing, and sales network is the foundation for further growth. In 2014, Bosch applied for some 4,600 patents worldwide. The Bosch Group's strategic objective is to create solutions for a connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is "Invented for life."

Exchange rate: 1 EUR = $1.32850

Additional information is available online at www.bosch.com, www.bosch-press.com, http://twitter.com/BoschPresse