New Generation of Hook and Loop Fastening Systems Uses VICTREX® PEEK(TM) Polymer

West Conshohocken, PA - (March 13, 2007) - When Aplix, the world leader in hook and loop fastening systems, developed a new method of molding a field of hooks within an injection molded part, it added VICTREX® PEEK(TM) polymer to its resin portfolio because of the polymer's high temperature resistance, enhanced stiffness and sterilizability. Using the high-performance thermoplastic in its patented Inter-Mold technology has enabled Aplix to produce a new generation of hook and loop systems for applications in a broad range of industries including hygiene, automotive, aerospace, packaging and more.

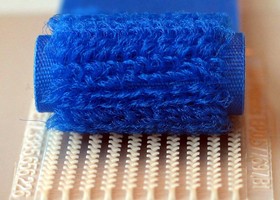

The Inter-Mold hooks are molded simultaneously with the plastic part and made out of the same resin. The hooks are, therefore, subject to the same specifications as the finished product - such as resistance to humidity, high temperature, chemicals and sterilization. The field of hooks can be designed in any shape and size and located anywhere on the molded part. This ensures high design flexibility and high performance in many different adjustable fastening systems.

Using the Inter-Mold technology enables the injection molding of readily deformable hooks that are an integral part of the plastic component - similar to a rib or cross rivet. This process includes a tool insert which can be readily mounted on a mold and in which the hook molds are integrated. During the ejection process the hooks are temporarily straightened. When cooled down, the parts return to their original shape.

In the aviation, aerospace and automotive industries, VICTREX PEEK polymer is used primarily because of its continuous temperature resistance up to 260 °C (500 °F) as well as its enhanced stiffness. The polymer is very stable in fire and demonstrates low smoke and gas emissions. It requires no flame-retardant additive to meet the V-0 classification of UL94 at 1.45-mm specimen thickness for the fire test. In addition, the polymer offers excellent chemical and solvent resistance.

In the hygiene market, where sterilization of products is of primary importance, VICTREX PEEK polymer offers excellent hydrolysis resistance. It resists the aggressive media and hot-steam sterilization that equipment and devices must undergo to be regularly cleaned and sterilized. Even storage for 2000 h at 200 °C (392 °F) and a pressure of 1.4 MPa (203 psi) does not lead to any significant changes in mechanical properties. The polymer is inherently pure with very low levels of extractable ions -only the lowest quantities of ionic constituents were determined by mass spectroscopy after specimens were stored in deionized water at 55 °C (131 °F) for 24 h.

The same hot-steam sterilization and high purity properties make VICTREX PEEK polymer an ideal choice for medical applications. In addition, it provides an excellent substitute for metal and is completely non-magnetic.

Victrex USA Inc., a division of Victrex plc, is the sole manufacturer and supplier of VICTREX PEEK polymer worldwide. For more information on the properties and performance advantages of VICTREX PEEK polymer, please call (800) VICTREX or visit the Victrex website at www.victrex.com